Posted by Spycor Building on Dec 3rd 2025

The process of building high-performance, moisture-managed exterior walls used to be synonymous with complexity, multiple steps, and soaring labor costs. If you are a contractor, home builder, or design professional, you know the frustration: juggling separate materials for your drainage plane and your stucco or manufactured stone lath, slowing down every project.

However, the industry standard is rapidly changing. Leading contractors and builders are streamlining their processes and boosting profitability by switching to a single, integrated solution: the DELTA®-DRY & LATH Rainscreen.

This revolutionary 2-in-1 product combines the function of a high-efficiency rainscreen with an innovative fiberglass lath, offering a complete moisture control system that dramatically simplifies the entire cladding process. This article details the three most compelling reasons why the DELTA®-DRY & LATH Rainscreen has become the go-to choice for superior wall assembly and efficient project completion.

The Core Problem: Complexity and Hazard

in Traditional Wall Assemblies

The traditional method for installing absorptive claddings—such as stucco, manufactured stone, or brick—involves a costly, multi-layer approach. First, a water-resistive barrier (WRB) is applied, followed by a separate drainage mat or rainscreen. Finally, a metal lath is fastened on top to receive the scratch coat.

This process is inherently flawed:

-

Redundant Steps: Two separate material installations (drainage and lath) mean double the measuring and double the fasteners, consuming valuable time.

-

Safety and Corrosion Concerns: Traditional metal mesh lath is heavy, sharp, and poses a risk to installers. Furthermore, metal lath is susceptible to corrosion from the alkalinity of cement-based scratch coats, compromising the wall assembly’s long-term integrity.

-

Moisture Trapping: Older systems often fail to provide adequate drainage and ventilation, leading to incidental moisture being trapped between layers, which can degrade the WRB and the structural sheathing.

The DELTA®-DRY & LATH Rainscreen solves these issues by creating a single, robust product that manages moisture, provides an alkali-resistant lath, and cuts installation time in half.

Reason 1: Unrivaled Installation Speed

and Labor Savings

The primary driver behind contractors switching to the DELTA®-DRY & LATH Rainscreen is its profound impact on the project timeline and labor expenditure. Time is money, and by eliminating an entire installation step, this product offers an immediate return on investment.

The Power of 2-in-1 Integration

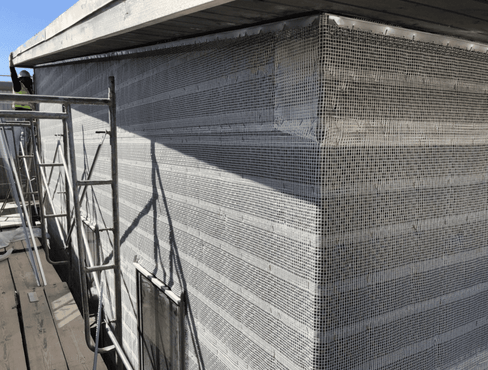

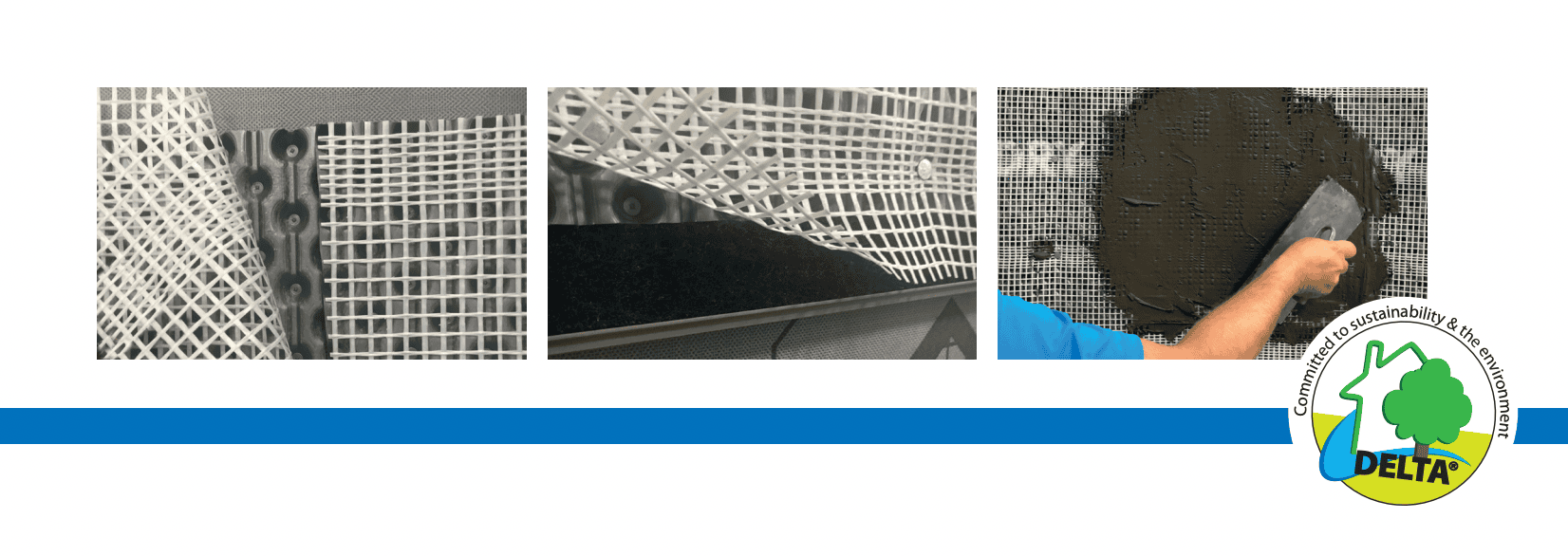

DELTA®-DRY & LATH Rainscreen is ingeniously engineered to merge two historically separate components: the dimpled High-Density Polyethylene (HDPE) rainscreen membrane and the alkali-resistant fiberglass lath. This means that with a single application, the installer establishes both the critical drainage and ventilation space, and the necessary reinforcement for the stucco or stone veneer.

By installing the DELTA®-DRY & LATH Rainscreen, you immediately reduce the number of fasteners required and the number of material transitions needed on the wall. This holistic approach ensures that the drainage plane and lath are perfectly aligned and secured simultaneously, minimizing human error and maximizing efficiency. For large-scale home builders, this translates into faster close times and reduced overhead. For custom home contractors, it means the ability to take on more projects without sacrificing quality.

Enhanced Jobsite Safety and Simplicity

The dangers associated with handling large rolls or sheets of traditional wire or metal lath are well-documented. Sharp edges cause cuts, increasing jobsite liability and slowing down workers who must handle the material cautiously.

The fiberglass lath pre-applied to the DELTA®-DRY & LATH Rainscreen is lightweight, flexible, and completely safe to handle, eliminating the risk of injury posed by sharp metal. This benefit often gets overlooked but is a major morale and liability factor that modern contractors prioritize. Furthermore, the rolls are sized for easy maneuverability—the DELTA®-DRY & LATH is available in rolls measuring 3.28' x 46' (151 sqft), making placement and securing straightforward for a small crew.

This seamless, safer application process is truly the number one reason high-volume contractors make the switch. They are not just buying a product; they are buying an optimized workflow.

Reason 2: Advanced Moisture

Management with Patented Air-Gap

Technology

The second crucial reason for the massive industry switch is the unparalleled performance of the DELTA®-DRY & LATH Rainscreen technology embedded within the product. Protecting a wall assembly from moisture is the single most important function of the building envelope, and DELTA®-DRY & LATH sets the gold standard.

Two-Sided Drainage for Total Protection

The core of the system is a dimpled membrane made of specialized HDPE. This structure creates a continuous air-gap behind the cladding. Unlike older or less sophisticated systems that offer minimal relief, this membrane provides true two-sided drainage and ventilation.

-

Exterior Side (Behind Cladding): The dimples create space between the lath and the membrane, allowing any water that penetrates the cladding (due to wind, rain, or capillary action) to quickly drain down and away from the wall assembly.

-

Interior Side (Behind Membrane): The unique groove design on the underside of the membrane ensures that any incidental moisture that makes it past the WRB can also escape and dry out.

This comprehensive approach prevents the accumulation of water, which is the root cause of mold, mildew, rot, and structural damage in exterior walls. The ability of the DELTA®-DRY & LATH Rainscreen to manage moisture on both sides of the membrane is a critical differentiator for building longevity.

Battling Solar-Driven Moisture

The ventilation provided by the continuous air gap is vital for addressing solar-driven moisture, a phenomenon where heat from the sun drives moisture vapor inward, trapping it within the wall system. The air cavity acts like a chimney, promoting convective air movement. This constant flow of air facilitates the quick drying of the entire wall assembly, ensuring that even under extreme weather conditions, the interior structure remains dry and protected.

By stopping solar-driven moisture and managing bulk water effectively, the DELTA®-DRY & LATH Rainscreen actively contributes to the long-term structural integrity and energy efficiency of the building.

Reason 3: Long-Term Durability and

Critical Code Compliance

The final, compelling reason why professionals choose this system is the inherent durability and the peace of mind that comes with using a rigorously tested and compliant product.

The Non-Corrosive Fiberglass Lath Advantage

For builders using stucco or manufactured stone, the choice of lath material is critical. Cementitious claddings are highly alkaline. Traditional galvanized or self-furred metal lath can corrode over time when exposed to the alkaline environment and incidental moisture, leading to "rust bleed" and, more importantly, a degradation of the entire lath system that holds the cladding.

The DELTA®-DRY & LATH Rainscreen utilizes an alkali-resistant fiberglass lath. This material is completely impervious to the chemicals in the scratch coat and is non-corrosive, guaranteeing that the lath maintains its strength and integrity for the lifetime of the cladding. This is a foundational factor in preventing future callbacks and costly repairs for both contractors and homeowners.

Meeting the Highest Industry Standards

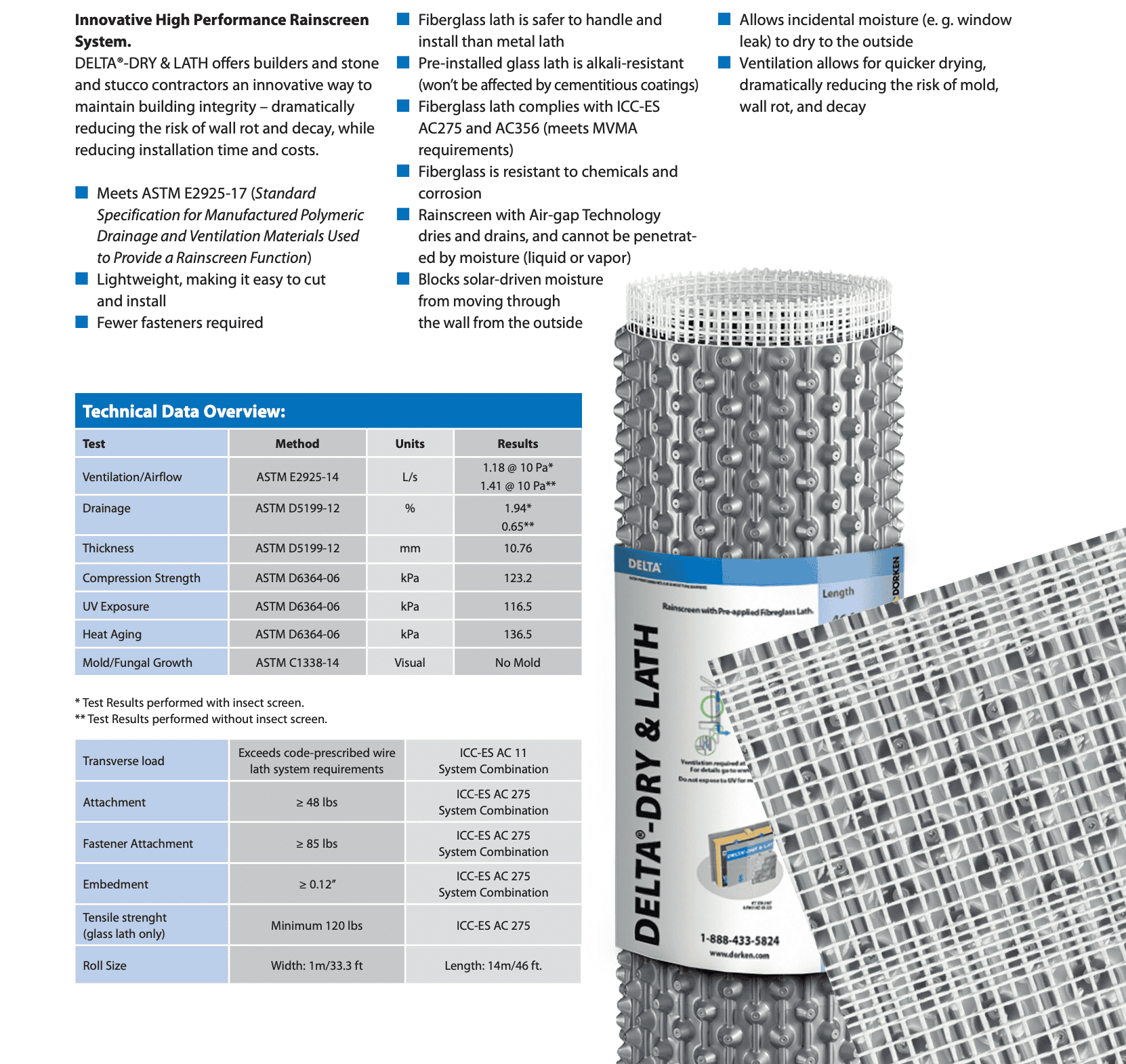

In today’s construction environment, material compliance is non-negotiable. The DELTA®-DRY & LATH Rainscreen has undergone stringent testing to ensure it meets and exceeds industry expectations. The pre-installed, alkali-resistant glass lath is in full compliance with ICC-ES AC 275 (Mesh-Reinforced Rainscreen requirements for Manufactured Stone Veneer), confirming its suitability for the most demanding applications. Furthermore, the rainscreen membrane meets ASTM E2925-17 (Standard Specification for Manufactured Polymeric Drainage and Ventilation Materials).

When specifying and installing DELTA®-DRY & LATH, professionals know they are using a product that is not only high-performing but also fully vetted and approved by independent evaluation agencies, solidifying their reputation for quality and adherence to modern building codes.

A Closer Look: Specifications of the

DELTA®-DRY & LATH Roll

For estimating and planning purposes, understanding the dimensions and specifications of the DELTA®-DRY & LATH Rainscreen is essential. The product is manufactured from durable High-Density Polyethylene (HDPE) with a thickness of 10.5 mm (approximately 7/16 inch), providing a generous air gap for drainage and ventilation.

The standard roll size is designed for easy handling and coverage efficiency, measuring 3.28 feet wide by 46 feet long, providing a total coverage of 151 square feet per roll. This combination of size and superior material performance ensures that contractors can accurately bid projects and minimize material waste on site.

The process of building high-performance, moisture-managed exterior walls used to be synonymous with complexity, multiple steps, and soaring labor costs. If you are a contractor, home builder, or design professional, you know the frustration: juggling separate materials for your drainage plane and your stucco or manufactured stone lath, slowing down every project.

However, the industry standard is rapidly changing. Leading contractors and builders are streamlining their processes and boosting profitability by switching to a single, integrated solution: the DELTA®-DRY & LATH Rainscreen.

This revolutionary 2-in-1 product combines the function of a high-efficiency rainscreen with an innovative fiberglass lath, offering a complete moisture control system that dramatically simplifies the entire cladding process. This article details the three most compelling reasons why the DELTA®-DRY & LATH Rainscreen has become the go-to choice for superior wall assembly and efficient project completion.

The Homeowner’s Investment: Peace of

Mind Protection

While the technical advantages of the DELTA®-DRY & LATH Rainscreen appeal directly to builders and contractors, the ultimate beneficiary is the homeowner. Investing in a home protected by this advanced moisture management system translates directly to:

-

A healthier indoor environment: By preventing moisture intrusion, the risk of mold and mildew growth within the walls is drastically reduced.

-

Reduced long-term maintenance costs: A non-corrosive lath and properly vented wall system extends the life of the cladding and the structure itself.

-

Superior protection: The peace of mind that comes from knowing the home is shielded by the best rainscreen and lath technology available on the market.

Conclusion

The evidence is clear: the DELTA®-DRY & LATH Rainscreen is not just an alternative to older construction methods; it is a fundamental upgrade to the entire wall assembly process. By integrating the rainscreen and fiberglass lath into one product, it delivers significant labor and time savings (Reason 1), establishes superior, two-sided moisture control (Reason 2), and guarantees long-term durability and essential code compliance (Reason 3). For any contractor or home builder serious about efficiency, quality, and preventing water damage, the choice to switch is simple and immediate.

Order Now at spycorbuilding.com and begin optimizing your wall assembly process with the DELTA®-DRY & LATH Rainscreen!

Frequently Asked Questions (FAQ)

What is DELTA®-DRY & LATH and how is it different from a traditional WRB?

DELTA®-DRY & LATH Rainscreen is a 2-in-1 moisture management system. Unlike a traditional Water-Resistive Barrier (WRB) which only stops water from passing through, the DELTA®-DRY & LATH also incorporates an innovative fiberglass lath and creates a continuous, ventilated air-gap. This air gap ensures any water that penetrates the cladding can drain away and allows trapped moisture vapor to dry out, a function a flat WRB alone cannot provide.

Is the fiberglass lath compatible with all types of stucco and stone?

Yes. The pre-installed lath is made from alkali-resistant glass fibers, meaning it will not react with or corrode from the high-alkaline content in conventional stucco, cementitious manufactured stone, or natural stone veneers. It is fully compliant for use with claddings requiring a scratch coat.

How does the 10.5 mm thickness benefit the wall assembly?

The 10.5 mm thickness of the DELTA®-DRY & LATH Rainscreen is crucial as it guarantees a sufficient space for the continuous air-gap. This substantial air space is vital for promoting effective convective ventilation and drainage, ensuring that bulk water is carried away and the wall can rapidly dry out, protecting the structural components.

Does DELTA®-DRY & LATH require special fasteners?

While it may use the same type of fastener (e.g., roofing nails or screws) that secures the WRB and the lath, the critical difference is the reduced quantity. Because the rainscreen and lath are installed simultaneously, you only need to fasten the assembly once, significantly reducing the number of fasteners required compared to installing a rainscreen and a separate lath.