Posted by Spycor Building on Jan 8th 2026

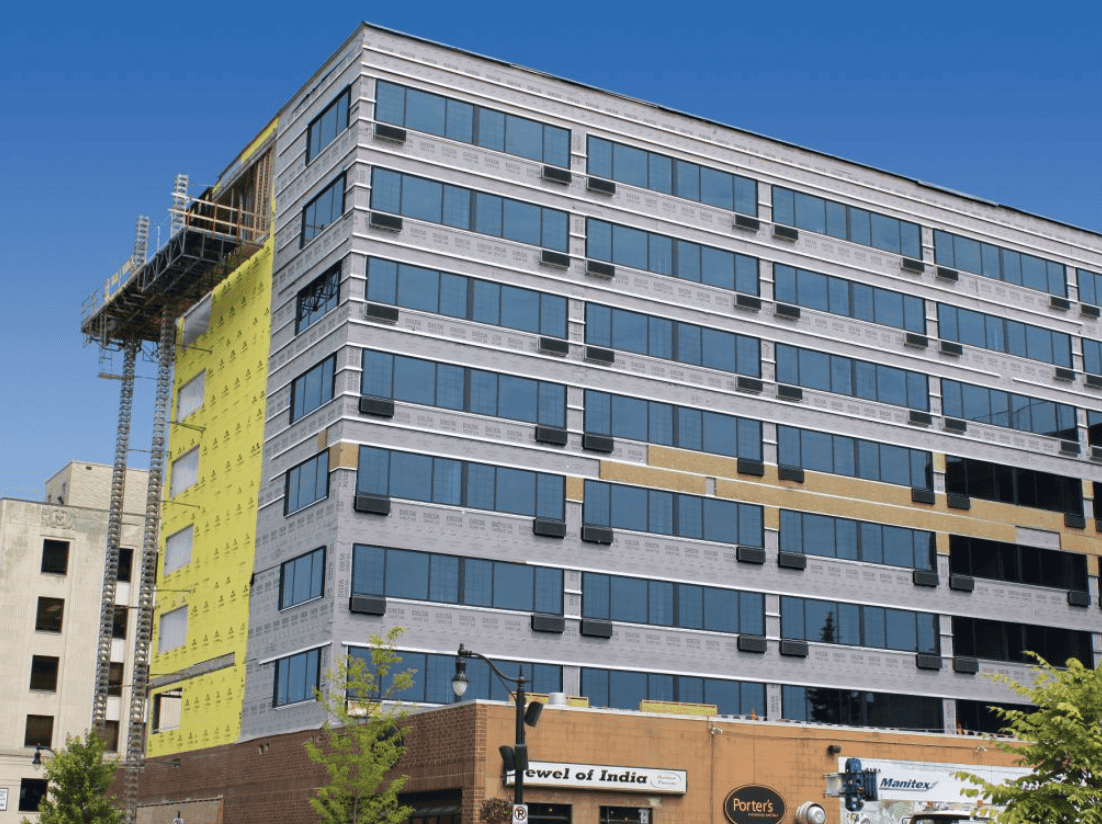

Home builders and contractors face mounting pressure to deliver projects that align with evolving energy codes, especially as airtightness standards tighten for commercial structures. DELTA®-VENT SA emerges as a reliable vapor permeable barrier solution, helping you meet these demands while enhancing overall building performance. This self-adhering air- and water-resistive barrier (WRB) not only prevents moisture ingress but also allows trapped vapor to escape, ensuring durable, energy-efficient envelopes. Sourced from trusted suppliers like Spycor Building, this product simplifies compliance for your next commercial build.

Navigating Upcoming Airtightness

Regulations for Commercial Builds

Commercial building codes are emphasizing stricter airtightness to curb energy loss and boost sustainability. Standards like ASHRAE 90.1 and the International Energy Conservation Code (IECC) are driving these changes, with maximum air leakage rates often capped at 0.35 cubic feet per minute per square foot (CFM/ft²) under specific pressure differentials. For builders tackling office spaces, retail centers, or multi-unit residential complexes, failing to achieve these levels can lead to costly rework, failed inspections, and higher operational expenses for clients.

Understanding these requirements starts with whole-building airtightness testing or envelope commissioning paths, as outlined in codes like those in the DC Building Code or IECC updates. Air leakage testing, such as blower door tests, measures infiltration rates, ensuring envelopes resist uncontrolled air movement. Non-compliance risks penalties, but proactive integration of high-performance materials like DELTA®-VENT SA can streamline the process. This vapor permeable barrier supports Level 3 air barrier performance per CAN/ULC S742 and ASTM E2357, making it a go-to for builders aiming to exceed baseline standards.

Contractors should prioritize materials that eliminate penetration leaks—common culprits in failed tests. DELTA®-VENT SA's fastener-free design addresses this directly, creating continuous seals that maintain integrity over time. By incorporating such barriers early in design, you can reduce heating and cooling loads by up to 25-40%, according to industry studies on airtight envelopes. This not only aids compliance but also positions your projects as forward-thinking, appealing to clients focused on long-term energy savings.

Why DELTA®-VENT SA Stands Out for

High-Performance Commercial Envelopes

For home builders venturing into commercial projects, selecting the right vapor permeable barrier is crucial to avoid moisture-related issues like mold or structural decay. DELTA®-VENT SA, a 3-layer system featuring spun-bonded polypropylene outer layers bonded to a watertight TPU core, offers 50 perms of vapor permeability—far surpassing many competitors. This allows moisture to diffuse outward while blocking external water, ideal for climates with high humidity or variable weather.

The product's self-adhering nature eliminates the need for mechanical fasteners, reducing potential leak points and labor time. With an exclusive self-adhering edge lap, overlaps remain airtight without additional tapes in many cases, though compatible adhesives like DELTA®-HF PRIMER for warm conditions or DELTA®-ADHESIVE for colder ones ensure versatility. Available in 4’ 11” x 115’ rolls, it's lightweight yet durable, handling job site rigors without tearing.

Builders appreciate its extended UV exposure ratings: up to 365 days in cooler climate zones, providing flexibility during construction delays. Certified under ICC-ESR 2932 and ABAA-approved, it meets U.S. and Canadian building codes, including NFPA 285 for fire-resistant assemblies with insulations like polyiso foam or mineral wool. This compatibility is key for commercial envelopes where fire safety intersects with airtightness goals.

Technical Specifications That Ensure

Compliance and Longevity

Diving into the specs, DELTA®-VENT SA delivers on airtightness with tested performance that aligns with 2026 code trajectories. Its air tightness meets the most stringent requirements, including Level 3 under CAN/ULC S742, which simulates real-world pressures and ensures minimal leakage. Vapor permeability at 50 perms facilitates drying in wall assemblies, preventing condensation that could compromise insulation effectiveness.

Health and sustainability certifications add value—it's Red List Compliant via DECLARE and has a Health Product Declaration (HPD 2.0), appealing to eco-conscious clients. In NFPA 285-compliant assemblies, it pairs with brands like Atlas, Carlisle, or Hunter polyiso, offering fire-rated options without sacrificing permeability.

Performance data underscores its edge: no fastener leaks mean consistent airtightness, potentially cutting energy consumption significantly. For contractors, this translates to easier blower door test passes and compliance documentation. Compared to traditional barriers, DELTA®-VENT SA's dimensionally stable construction resists wrinkling, ensuring flat, effective coverage.

Real-World Energy Savings and Durability

in Commercial Projects

Beyond compliance, DELTA®-VENT SA drives tangible benefits for your building projects. By creating airtight envelopes, it minimizes air infiltration, slashing heating and cooling costs—essential as energy prices rise. Builders report improved indoor air quality and occupant comfort, reducing mold risks and extending structure life.

In commercial settings, such as office towers or retail spaces, this barrier supports smaller HVAC systems, cutting upfront costs. Its vapor permeability ensures walls dry out, preventing issues in high-occupancy buildings where internal moisture loads are high. Durability shines in harsh weather; the spun-bonded PP layers resist punctures, maintaining performance over decades.

Integrating this barrier aligns with 2026 trends toward all-electric, heat-pump-ready designs, where tight envelopes are non-negotiable. It's a smart investment that pays off in efficiency and resilience.

Order Now at spycorbuilding.com to secure DELTA®-VENT SA for your next project and stay ahead of 2026 compliance demands.

FAQ: Answering Key Questions for

Builders and Contractors

What makes DELTA®-VENT SA suitable for 2026 airtightness compliance? Its Level 3 air barrier rating and fastener-free design ensure continuous seals, meeting ASHRAE and IECC leakage limits while allowing vapor escape.

Can DELTA®-VENT SA be used in all climate zones?

Yes, with UV exposure up to one year in most zones, it's versatile for various regions, though primers adjust for temperature extremes.

How does it compare to traditional vapor barriers?

Unlike impermeable options, its 50 perms permeability prevents trapped moisture, reducing mold risks and enhancing energy efficiency.

Is installation training required?

No formal training needed, but Dörken's guides and videos make it straightforward; self-adhering laps simplify overlaps.

What substrates work best with DELTA®-VENT SA?

It bonds to wood, masonry, concrete, and more; use primers for optimal adhesion on challenging surfaces.

Does it comply with fire safety standards?

Absolutely—NFPA 285 compliant in tested assemblies with common insulations.

How long does the adhesive last?

Long-term adhesion eliminates leaks, backed by rigorous testing for durability.