Posted by Spycor LLC on Jan 27th 2026

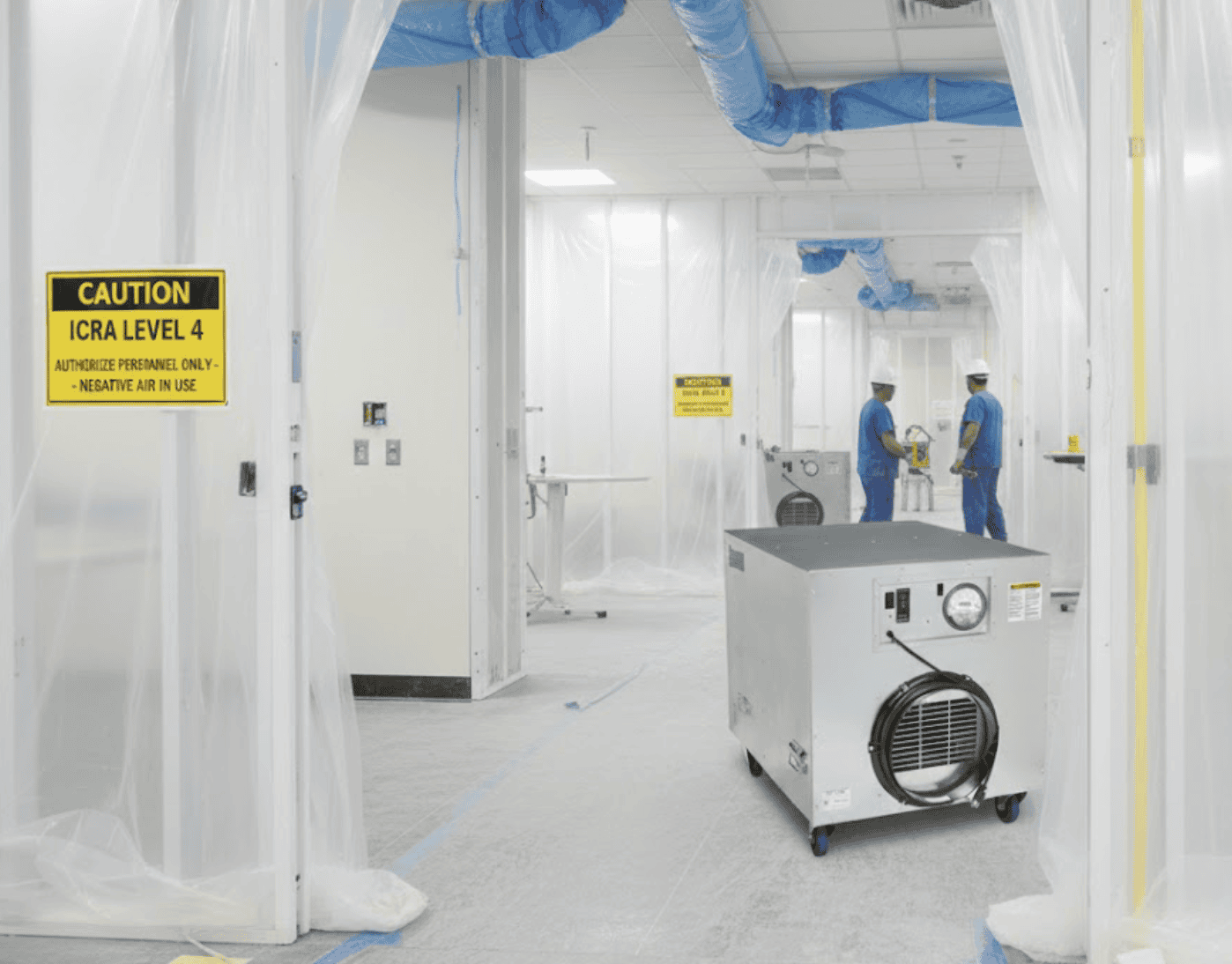

Managing air quality in a healthcare environment isn’t just about comfort; it’s about infection control and patient safety. When performing construction, renovation, or maintenance in a hospital, specialized contractors must adhere to strict ICRA (Infection Control Risk Assessment) guidelines to prevent the spread of Aspergillus and other airborne pathogens.

To maintain Class IV compliance, you need industrial-grade equipment that guarantees 99.97% filtration efficiency and reliable negative pressure.

Below is a technical breakdown of the top-performing HEPA air scrubbers and negative air machines currently available at Spycor Environmental, specifically selected for healthcare facility managers and specialized contractors.

1. Abatement Technologies PRED750

Predator Portable Air Scrubber

Best for Tight Spaces and Patient Room Renovation

The PRED750 Predator is the industry standard for contractors who need high-performance filtration in a compact, highly portable footprint. In healthcare construction, space is often at a premium. The PRED750 is designed to fit through standard doorways and operate quietly enough for use near active patient care areas.

-

Airflow Performance: Delivers up to 750 CFM, making it ideal for smaller containment zones or individual patient room renovations.

-

True HEPA Filtration: Each unit features a long-life HEPA filter tested and certified to capture 99.97% of particles down to 0.3 microns.

-

Durability: The rotational-molded plastic cabinet is not only dent-resistant but also easy to sanitize—a critical requirement for moving equipment between different hospital wings.

Why it’s ICRA-compliant: It provides the consistent negative pressure required to ensure dust and microbes stay inside the containment area, protecting the rest of the facility.

View Specs and Pricing for the PRED750 at Spycor.com

2. Predator 1200 Portable Air Scrubber

with UV-Light

Best for High-Risk Environments & Germicidal Irradiation

When working in high-risk areas—such as oncology wards or surgical suites—standard HEPA filtration may be supplemented with UV technology. The Predator 1200 combines high-volume airflow with an integrated UV-C germicidal lamp.

-

Variable Airflow (300 CFM – 1,000 CFM): The variable speed control allows you to dial in the exact amount of negative pressure needed, preventing "over-vacuuming" of small containment tents.

-

UV-C Germicidal Technology: The internal UV light helps neutralize bacteria and viruses trapped on the filters, providing an extra layer of protection for both the operator and the facility.

-

High Capacity: With a peak of 1,000 CFM, this unit can handle larger renovation zones while maintaining a manageable 70-pound weight for easy transport.

Why it’s ICRA-compliant: The combination of medical-grade HEPA and UV-C light meets the most stringent requirements for "Airborne Infection Isolation" support during construction.

3. Abatement Technologies 2-Speed HEPA

Negative Air Machine

Best for Large-Scale Construction & Structural Containment

For large-scale hospital expansions or heavy demolition, you need a high-capacity Negative Air Machine (NAM). This 2-speed powerhouse from Abatement Technologies is built for continuous, 24/7 operation in the most demanding environments.

-

Differential Pressure Gauge: This built-in gauge is a critical safety feature. It allows facility managers to monitor filter loading in real-time, ensuring the machine never drops below the required pressure threshold.

-

Two-Speed Operation: Allows for 2,000+ CFM (High) for rapid air exchanges or a lower setting for maintained containment during off-hours.

-

Heavy-Duty Construction: Designed for the rigors of a construction site, this unit features a galvanized steel housing that stands up to heavy impact.

Why it’s ICRA-compliant: The inclusion of a differential pressure gauge simplifies compliance documentation. It provides visual proof that the machine is operating within the specified parameters required by hospital safety officers.

Critical Features: What Makes an Air

Scrubber "Medical Grade"?

When auditing your fleet for healthcare use, ensure your equipment meets these four pillars of ICRA compliance:

-

Individually Certified HEPA Filters: Avoid "HEPA-type" filters. Only True HEPA (99.97% @ 0.3 microns) is acceptable for hospital dust containment.

-

Positive Pressure Seals: Look for machines where the HEPA filter is gasket-sealed against the frame. This prevents "leak-by," where contaminated air bypasses the filter.

-

Non-Marking Casters: Hospital floors are expensive. Professional-grade machines use non-marking rubber wheels to prevent damage to linoleum and epoxy coatings.

-

Easy-to-Clean Housing: Equipment must be wiped down with disinfectants before entering and after leaving a healthcare facility. Smooth, non-porous surfaces (like the Predator’s poly-cabinet) are preferred.

Explore our full range of Construction Portable Negative Air Machines and ensure your next healthcare project is 100% compliant.

Upgrade Your Infection Control Strategy Today

Don't risk a project shutdown or a healthcare-acquired infection (HAI) lawsuit due to inferior air filtration. Invest in the gold standard of healthcare construction equipment.

Shop the Top 3 Recommended Units:

-

PRED750 Compact Air Scrubber - Best for portability.

-

Predator 1200 with UV-C - Best for high-risk zones.

-

Abatement Technologies 2-Speed NAM - Best for large-scale demolition.

Frequently Asked Questions (FAQ)

What is the difference between an air scrubber and a negative air machine?

An Air Scrubber recirculates air within a space to clean it. A Negative Air Machine is ducted to exhaust air outside the containment area, creating a vacuum (negative pressure) that prevents dust from escaping. Most high-end units, like the Abatement Technologies Predator series, can perform both functions depending on how they are ducted.

How often should I change filters in a hospital setting?

In a healthcare environment, the Pre-filters should generally be changed daily or every few days depending on the dust load. The HEPA filter should be changed when the pressure gauge indicates restricted airflow or after a project involving hazardous materials. Always change filters inside the containment zone to prevent cross-contamination.

Do these machines meet ICRA Class IV requirements?

Yes. When used as part of a proper containment strategy (including barrier walls and pressure monitoring), the PRED750, Predator 1200, and Abatement NAM provide the certified HEPA filtration and negative pressure required for ICRA Class IV compliance.

Can I duct the Predator 1200 through a ceiling tile?

Yes, the Predator 1200 is designed for easy ducting. Using a ceiling discharge kit, you can exhaust the filtered air into the plenum space, which is a common practice for hospital renovations.

Is UV-C light necessary for ICRA compliance?

While not strictly required by all ICRA standards, UV-C is increasingly requested by Hospital Epidemiologists and Infection Control Practitioners in high-sensitivity areas to neutralize biological contaminants like mold spores and bacteria.