Posted by Spycor LLC on Dec 16th 2025

In specialized construction fields such as mold, asbestos, lead abatement, and water damage restoration, controlling the air quality is not just a best practice—it is a non-negotiable legal and safety requirement. The primary tool for achieving this containment is the Negative Air Machine (NAM), also commonly referred to as a HEPA air scrubber.

A professional-grade Negative Air Machine for remediation projects is essential for protecting building occupants, adjacent spaces, and, most critically, your workers. The right NAM must combine high CFM (Cubic Feet per Minute) airflow with true HEPA filtration to create the necessary containment zone and prevent the dangerous spread of microscopic contaminants.

This comprehensive guide reviews the key features, performance metrics, and top models available at Spycor Environmental to help contractors select the best Negative Air Machine for the most challenging remediation jobs.

The Science of Containment: Why

Negative Air Pressure is Necessary

During demolition, abatement, and drying processes, dormant contaminants like mold spores, asbestos fibers, or lead dust become airborne. These particles are typically microscopic (less than 10 microns) and can easily escape a work area, contaminating clean environments.

The Negative Air Machine solves this problem by utilizing the principle of negative pressure containment:

-

Air Extraction: The NAM draws air out of the work zone and exhausts it (after rigorous filtration).

-

Pressure Differential: Because air is being constantly removed, the pressure inside the containment area drops slightly below the pressure of the surrounding clean areas.

-

Controlled Airflow: This pressure differential ensures that any airflow moves into the containment zone through any gaps or breaches, never out. This creates a sealed, one-way system that effectively traps airborne hazards.

This process requires a HEPA air scrubber that is powerful, reliable, and equipped with certified filtration.

Key Performance Factors in Choosing a

Negative Air Machine

Selecting the best Negative Air Machine for remediation projects involves evaluating several non-negotiable technical specifications:

1. Certified HEPA Filtration

The most critical component is the HEPA filter. HEPA (High-Efficiency Particulate Air) filters must capture 99.97% of particles at 0.3 microns. Mold spores, asbestos fibers, and lead dust all fall within the size range that HEPA filtration effectively traps.

-

Certification: Ensure the unit uses a D.O.P. tested and certified HEPA filter. This is non-negotiable for professional abatement work.

-

Filter Stages: Most quality NAMs use a multi-stage filtration system: a primary pre-filter (to catch large debris), a secondary filter (to protect the HEPA), and the final HEPA filter. This extends the life of the expensive HEPA filter.

2. Airflow (CFM) and Air Changes Per Hour (ACH)

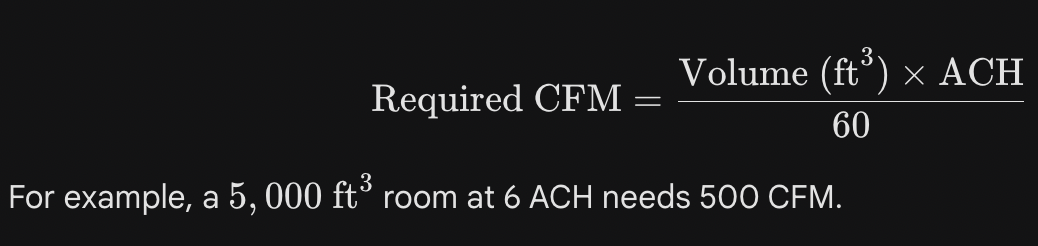

The capacity of the NAM is measured in CFM. The required CFM for a job depends on the size of the containment area, dictated by the number of Air Changes Per Hour (ACH) you need to achieve.

-

Industry Standard: Most remediation standards require 4 to 6 ACH.

-

Calculation: To determine the required CFM:

-

Versatility: Look for a NAM with variable speed control to match the required CFM to the size of the containment zone, maximizing efficiency and controlling noise.

3. Static Pressure and Motor Reliability

Static Pressure is the force the fan generates to pull air through dense ductwork and clogged filters. Remediation air scrubbers must have powerful motors capable of maintaining high CFM even as the filters load up.

-

Motor: Commercial-grade, continuous-duty motors (often 1 HP or more) are required for the demanding 24/7 run times typical in drying and abatement projects.

-

Housing: Look for durable, dent-proof housings (e.g., roto-molded polyethylene) that can withstand the rigors of construction transport and job site handling.

Top-Rated Negative Air Machines for

Professional Contractors

At Spycor Environmental, the following Omniair models consistently lead the market for performance, reliability, and filtration integrity in demanding remediation projects:

1. Abatement Technologies PRED750

The Abatement Technologies PRED750 Predator Portable Air Scrubber is the industry standard for portable, high-performance HEPA air scrubbers.

-

Performance: Operates at a powerful 750 CFM (nominal), making it highly versatile for small-to-medium containment areas.

-

Filtration Integrity: Features a state-of-the-art filter gasket system that prevents bypass leakage—a critical safety feature in asbestos and lead abatement.

-

Portability: Weighing only 85 lbs, its compact size and rugged polyethylene housing allow for easy transport and stacking.

-

Feature Highlight: Includes a filter change indicator light and variable speed control, optimizing performance and extending filter life.

2. Omniaire OA2000V HEPA Negative Air Machine (High Volume)

The Omniaire OA2000V is the solution for large commercial and industrial containment zones, offering robust, high-volume air movement.

-

High CFM: Delivers a massive variable airflow from 400 to 1,600 CFM, making it suitable for large-scale mold, lead, and asbestos remediation.

-

Versatility: The adjustable airflow allows contractors to precisely meet the required ACH for various room sizes without needing multiple units.

-

Motor: Equipped with a powerful and efficient motor engineered for heavy-duty, continuous operation.

-

Construction: Built with a durable, lightweight polyethylene housing designed for rugged job site conditions and easy transport.

3. Omniaire OA600V HEPA Negative Air Machine (Portable)

The Omniaire OA600V is the ideal choice for contractors who need portability and dependable performance for smaller, confined spaces.

-

Performance: Features variable airflow from 150 to 600 CFM, providing excellent negative pressure control for single rooms, closets, or residential containments.

-

Size Advantage: Its compact and lightweight design makes it highly maneuverable and easy to transport up stairs or into tight areas where larger machines cannot go.

-

Efficiency: Despite its small size, it utilizes true D.O.P. tested HEPA filtration, ensuring the same level of contaminant capture as its larger counterparts.

-

Application: Perfect for creating an air barrier in sensitive areas or serving as a dedicated HEPA air scrubber during post-remediation cleaning.

Integrating Your Negative Air Machine

into the Project

The NAM is only as effective as the containment zone it serves. Proper setup is crucial for negative pressure containment.

1. Sealing the Containment

The work area must be sealed airtight using polyethylene sheeting, zipper doors, and duct tape. Any leaks reduce the NAM's effectiveness. The NAM's exhaust is then ducted outside the structure or into a clean, controlled area.

2. Placement and Air Direction

Place the NAM strategically so that the air entrance point is as far as possible from the air exhaust point. This ensures that the air is drawn across the entire work area before being cleaned, maximizing the Air Changes Per Hour throughout the entire containment zone.

3. Remote Monitoring

For high-risk remediation projects, a manometer or pressure gauge must be used to continuously monitor the pressure differential (typically aiming for to inches of water column). This verification step confirms that the negative pressure containment is being actively maintained.

Conclusion: Securing Health and

Compliance

The decision to purchase a high-quality Negative Air Machine is an investment in safety, compliance, and your reputation. Relying on sub-standard equipment exposes your business to liability and, more importantly, endangers the health of your crew and clients.

The top-tier HEPA air scrubbers from Abatement Technologies and Omniair, available at Spycor Environmental, provide the necessary combination of certified HEPA filtration, robust CFM capacity, and job site durability to handle the most challenging abatement and remediation projects with confidence. Ensure your next job meets the highest standards of safety and professional execution

Order Now atFrequently Asked Questions (FAQ)

What does "D.O.P. Tested and Certified HEPA Filter" mean?

D.O.P. stands for Dispersed Oil Particulate. It is the gold standard integrity test that ensures a filter achieves the mandatory 99.97% efficiency at 0.3 microns. For high-risk remediation projects (especially asbestos abatement), the HEPA filter and often the machine itself must be certified to have passed this leakage test.

How do I know how many CFMs I need for my remediation containment area?

You need to calculate the volume of your room (Length Width Height in feet). Then, multiply the volume by the desired Air Changes Per Hour (ACH), typically 4 to 6 for remediation, and divide by 60 minutes.

Can I use a Negative Air Machine for dust collection on a construction site?

Yes. While designed for remediation, HEPA air scrubbers are also the most effective devices for general construction dust control, woodworking, and capturing fine particulates (like sanding dust or drywall dust) in any setting that requires clean air, often referred to as air scrubbing.

What is the main benefit of the Omniair OA2000V's variable speed control?

The variable speed control (400 to 1,600 CFM) allows contractors to precisely adjust the airflow to meet the exact CFM required for any size containment area. This saves money on filter life and energy costs, and ensures compliance by preventing the creation of too much negative pressure, which can damage structures or containment barriers.

Is a "Negative Air Machine" the same as a "HEPA Air Scrubber"?

They are often the same machine used for different purposes. A machine creating negative pressure containment is functioning as a Negative Air Machine. If the same unit is simply placed in a room to clean the air without creating a pressure differential, it is functioning as a HEPA Air Scrubber. Most professional units perform both functions.