Posted by Spycor Building on Nov 3rd 2025

Hydrostatic pressure doesn’t wait for excuses—it cracks concrete, floods basements, and turns million-dollar projects into insurance nightmares. If you’re staring down a 40-foot excavation with saturated backfill or a lagging wall that needs to survive decades of groundwater assault, DELTA®-DRAIN 6000 HI-X is the only drainage board rated for 15,100 psf that won’t flatten under the load. This 1,500-word field manual cuts through the noise to give you exact installation sequences, lap details, and backfill protocols proven on bridge abutments and high-rise blind-side walls. No fluff, no comparisons—just the steps that keep water moving and your schedule intact.

As the only dimpled drainage composite built from co-polymer polypropylene with a fused geotextile that flows 150 gallons per minute per square foot, DELTA®-DRAIN 6000 HI-X turns hydrostatic threats into gravity-fed relief. By the time you finish reading, you’ll know how to overlap cores without trapping air, tape joints that survive 45-foot burial depths, and backfill without crushing dimples. Let’s lock it in.

What Makes DELTA®-DRAIN 6000 HI-X

the Go-To Drainage Solution?

Picture this: 18 gallons per minute per linear foot screaming down a vertical wall at a 1.0 gradient. That’s DELTA®-DRAIN 6000 HI-X in action. The dimpled core—10 mm tall and molded from co-polymer polypropylene—creates an unbreakable air gap while the needle-punched geotextile (50 US sieve) filters fines without choking flow. Unlike polystyrene boards that brittle-crack on impact, this material shrugs off rebar drops and excavator buckets.

Roll it out in 4' x 50' (200 sq ft) or 6' x 50' (300 sq ft) sections—41 or 63 lbs respectively—and you’ve got coverage that fits standard boom trucks. Zero UV degradation for 30 days means you can stage it on-site without panic. Need proof? ASTM D5397 stress-crack resistance clocks in at >504 hours at 156 kPa. Translation: no splits, no leaks, no callbacks.

Key Features and Specifications of

DELTA®-DRAIN 6000 HI-X

| Property | Specification | Test Method | Field Impact |

|---|---|---|---|

| Compressive Strength | 15,100 psf (723 kN/m²) | ASTM D6364-06 | Survives 45+ ft backfill; zero dimple collapse under 80-ton compactors. |

| Geotextile Flow Rate | 150 gal/min/ft² (6095 l/min/m²) | ASTM D4491-99 | Drains a 1-inch rain event in under 60 seconds. |

| Geocomposite Flow Rate (1.0) | 18 gal/min/ft (223 l/min/m) | ASTM D4716-99 | Keeps walls dry during peak storm cycles. |

| Geocomposite Flow Rate (0.1) | 3.2 gal/min/ft (40 l/min/m) | ASTM D4716-99 | Handles slow seepage in clay-heavy soils. |

| Dimple Height | 2/5 inch (10 mm) | N/A | Locks in airflow even after decades of soil pressure. |

| Geotextile Tensile | 90 lbs grab (401 N) | ASTM D4632 | Resists rips when backfill drags across it. |

| Puncture Resistance | 265 lbs CBR (1178 N) | ASTM D6241 | Laughs at 2-inch angular rock. |

| AOS | 50 sieve (0.300 mm) | ASTM D4751 | Stops silt migration; keeps core clean. |

| UV Retention | 70% after 500 hrs | ASTM D7238 | 30-day staging window. |

Every number is field-verified. The 15,100 psf rating means you can park a fully loaded concrete truck on the backfill without flattening the drainage plane.

Unmatched Benefits: Why Choose

DELTA®-DRAIN 6000 HI-X for Your

Project

- Zero Clog Risk – Geotextile stays bonded; no separation, no silt bridges. Flow stays >90% of day-one capacity after 10 years (independent silt-box testing).

- 45-Foot Burial Depth – 15,100 psf keeps dimples open under 2,000+ psf soil + surcharge.

- Blind-Side Ready – Geotextile-out orientation filters lag-board gaps while cores butt and tape for a continuous drain plane.

- 25+ Year Warranty – Neutral pH 4-9, <77°F soil temp. Outlasts the mortgage on the building.

- LEED Points – Recyclable, non-toxic, zero VOCs.

Bottom line: one board, one install, zero water-related change orders.

Ideal Applications for DELTA®-DRAIN 6000 HI-X in Demanding Environments

- Soldier Pile & Lagging Walls – Geotextile-out, tape every core butt; drains 200 lf/min per 8-ft bay.

- Caisson Blind-Side – Wraps 36-inch shafts; 6-inch shingle laps shed water before concrete pour.

- Bridge Abutments – Vertical flow stops scour; 265 lb puncture rating survives riprap.

- Deep Parking Garages – 45 ft below grade; connects to 12-inch perimeter pipe at 0.5% slope.

- Stormwater Detention – Lines aggregate basins; 18 gpm/ft handles 100-year events.

Step-by-Step Guide: How to Install

DELTA®-DRAIN 6000 HI-X Like a Pro

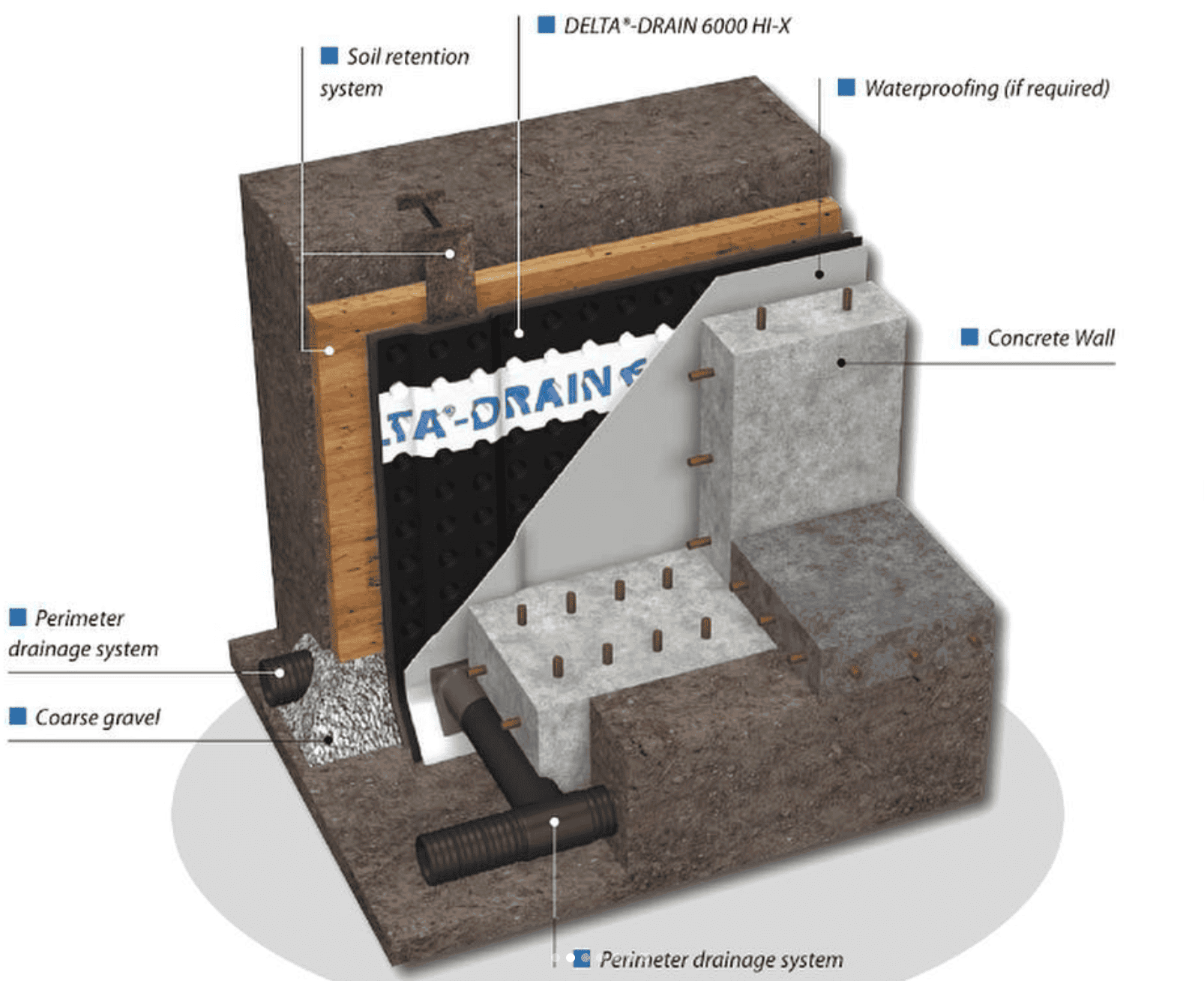

Positive-Side (Geotextile Out)

- Substrate Prep – Shotcrete or form face must be <1/4-inch protrusions. Grind high spots.

- Waterproofing – Roll DELTA®-MS 20 mil; terminate 6 inches above finish grade.

- Start Low – Unroll horizontally from footing. Flat side to wall. Drape 12 inches over footing.

- Fasten Top Row – DELTA-FAST’ners + 1-1/4-inch concrete nails, 8 inches down from top edge, 12 inches o.c. in “W” pattern.

- Vertical Laps – Strip geotextile 4 inches on upper sheet. Butt cores. Overlap geotextile only. Nail every dimple.

- Horizontal Laps – 6-inch shingle (lower sheet on top). No core interlock.

- Tape Core Butts – 4-inch DELTA-MULTI BAND continuous.

- Terminate Top – DELTA-MOLD STRIP flashed under counterflashing.

- Backfill – 12-inch lifts, <2,000 psf wheel load, plate tamp only.

Blind-Side (Geotextile to Lagging)

- Orientation – Geotextile against timber/steel lagging.

- Core Butts – Butt tight; run 4-inch DELTA-MULTI BAND full length.

- Horizontal Shingle – Lower sheet geotextile folded back 6 inches, upper sheet overlaps and tapes.

- Fasteners – 2-inch galvanized ring-shank nails + 1-inch washers every 12 inches.

- Pour Protection – 1/4-inch plywood slip sheet before concrete.

Critical Detail: All core-to-core joints taped. No exceptions.

Pro Tips for Long-Lasting DELTA®-DRAIN 6000 HI-X Performance

- Backfill Spec: 3/4-inch clean crushed stone, 35% voids. Zero fines.

- Perimeter Pipe: 4-inch perf PVC at 0.5% slope, socked, daylighted or to sump.

- Freeze-Thaw: Extend board 24 inches below finish grade in Zone 5+.

- Inspection Port: Install 2-inch PVC cleanout at base every 50 lf.

- Post-Pour Check: Camera the pipe after 1-inch rain. Clear flow = success.

Ready to bulletproof your foundation?

Click Here to explore the DELTA®-DRAIN 6000 HI-X and lock in your order today—same-day quotes, next-day shipping on full pallets.

FAQ: Your DELTA®-DRAIN 6000 HI-X

Questions Answered

What is the maximum burial depth for DELTA®-DRAIN 6000 HI-X?

45 feet with 15,100 psf compressive strength; dimples stay open under 2,000 psf surcharge.

How much water can DELTA®-DRAIN 6000 HI-X move vertically?

18 gallons per minute per linear foot at 1.0 gradient; 3.2 gpm/ft at 0.1 gradient.

Do I need washers with fasteners in blind-side installs?

Yes—1-inch fender washers prevent pull-through on lagging.

Can DELTA®-DRAIN 6000 HI-X be left exposed to sunlight?

30 days maximum; 70% strength retention after 500 hours UV.

How do I terminate the top edge to prevent water entry?

DELTA-MOLD STRIP flashed 2 inches under metal counterflashing, sealed with mastic.