Posted by Spycor Building on Nov 5th 2025

When constructing any structure built upon a concrete slab—whether it's a commercial warehouse, a residential basement, or a high-traffic facility—builders face a silent, persistent threat: moisture migration. The soil beneath a concrete slab is an endless source of water vapor. Since concrete is naturally porous, this vapor is continually pulled upward through capillary action, a process often referred to as moisture wicking. Without a robust and effective underslab vapor barrier, this moisture compromises the entire building envelope, leading to mold, structural degradation, and costly flooring failures.

This pervasive challenge requires a technologically advanced solution, not a simple plastic sheet. The best practice in modern building science is to create a perpetual moisture defense system. The single most effective product for achieving this is DELTA-MS UNDERSLAB, a high-density polyethylene (HDPE) dimpled membrane specifically engineered to provide superior protection. It is a fundamental component of moisture management, designed to ensure the longevity and health of structures built on grade.

The Critical Need for a Concrete Slab

Moisture Barrier

Ignoring underslab moisture is an expensive oversight. When water vapor moves through the concrete, it doesn't just evaporate; it causes a cascade of destructive effects:

-

Flooring Failure: Adhesives for tile, wood, carpet, and other floor coverings are highly susceptible to moisture. High moisture vapor transmission rates (MVTR) can cause adhesives to re-emulsify or break down, leading to bubbling, cracking, and detachment. This premature flooring failure is one of the most common and costly issues in construction.

-

Structural Integrity: Constant moisture intrusion can accelerate the corrosion of embedded metal components, such as reinforcing steel (rebar), reducing the concrete's strength and leading to spalling or cracking over time.

-

Indoor Air Quality (IAQ): Where there is moisture and organic material, there is potential for mold and mildew growth. This can severely degrade IAQ, leading to health issues for occupants.

-

Sub-Base Degradation: Traditional, weaker vapor retarders can be easily damaged during the construction process, rendering them useless before the concrete is even poured.

To combat these issues, the building industry has moved toward using premium HDPE dimpled membranes like DELTA-MS UNDERSLAB, which goes beyond simple vapor retarding to active moisture management.

Introducing DELTA-MS UNDERSLAB: A

Paradigm Shift in Moisture Control

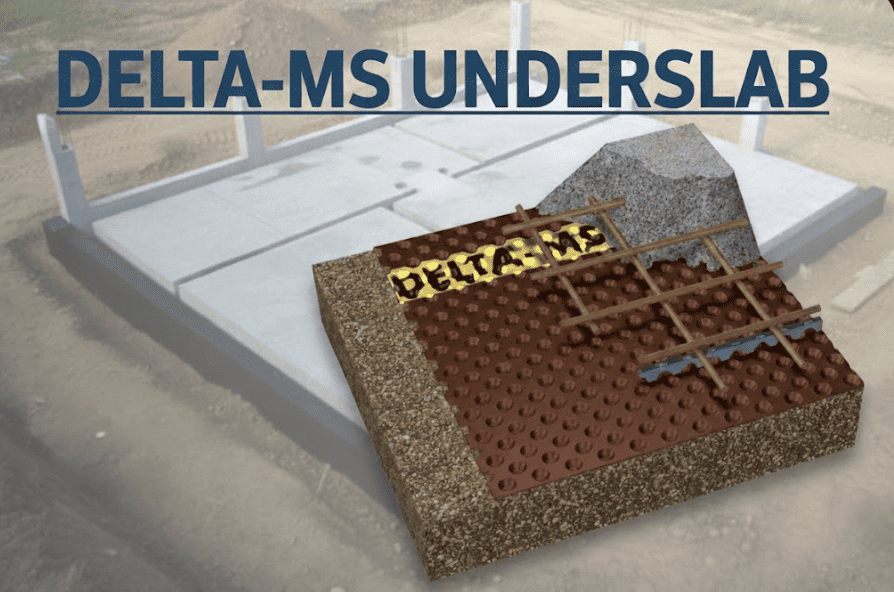

DELTA-MS UNDERSLAB is not merely a sheet of plastic; it is a meticulously engineered concrete slab moisture barrier system. Its core innovation lies in its unique, durable, and highly resilient construction, which fundamentally changes how moisture is handled beneath the slab.

The product is a massive, highly durable dimpled sheet made from high-density polyethylene (HDPE). This material choice is crucial: HDPE is chemically resistant and inherently waterproof, providing a near-zero perm rating that blocks almost all vapor transmission.

The Power of the Dimpled Structure: Creating an Air Gap

Unlike conventional flat-sheet vapor barriers that lie directly against the sub-base, the defining feature of the DELTA-MS UNDERSLAB is its patented dimpled configuration. When laid down, these dimples face the sub-base, creating a permanent, continuous air gap—a capillary break—between the membrane and the soil.

This air gap serves two indispensable functions:

-

Capillary Break: It prevents the concrete from ever coming into direct contact with the moisture-saturated sub-base, effectively cutting off the capillary action responsible for wicking water up into the slab.

-

Pressure Equalization: Any water or vapor that manages to pass through the sub-base is channeled into this air gap, where the pressure is neutralized, and the moisture can disperse or drain away laterally, preventing localized build-up against the concrete.

This advanced design makes DELTA-MS UNDERSLAB an essential component for any slab-on-grade construction aiming for the highest standards of durability and performance.

Key Technological Advantages of DELTA-

MS UNDERSLAB

The performance and reliability of this product stem from its adherence to stringent building science principles and its robust features, which set it apart from typical construction-grade polyethylene films.

1. Unmatched Compressive Strength and Durability

The robust HDPE material and the dome-shaped dimples give DELTA-MS UNDERSLAB exceptional compressive strength. This is vital during the construction phase, as the membrane must withstand the traffic of workers, wheelbarrows, and rebar placement without tearing or being compromised. A breach in a traditional vapor barrier can doom the project, but the engineered strength of DELTA-MS UNDERSLAB provides a significant margin of safety and ensures the continuity of the protective layer.

2. Near-Zero Permeance Rating

The perm rating is the measure of a material's ability to resist water vapor transmission. To qualify as a true vapor barrier, a material must meet a rigorous standard. DELTA-MS UNDERSLAB’s HDPE construction achieves an incredibly low perm rating, far surpassing the requirements for an effective underslab vapor barrier. This exceptional resistance is critical for protecting moisture-sensitive flooring materials and maintaining the interior environment's integrity.

3. Protection Against Chemical Attack

Concrete foundations are exposed to various compounds in the soil, including potential salts and alkalis. The HDPE material is highly resistant to these common soil contaminants, ensuring that the integrity of the barrier is not compromised over the decades. This chemical resistance contributes directly to the long-term protection of the concrete slab itself.

4. System Integration and Sealing

A vapor barrier is only as strong as its weakest link, which is often the seam. DELTA-MS UNDERSLAB is designed to be part of a complete system. The wide rolls (available in sizes like 9’ 10”, 8.0 ft, 7.0 ft, and others) minimize the number of seams needed. Furthermore, specialized tape and accessories are used to secure the overlaps and seal the perimeter at foundation walls, creating a continuous, monolithic barrier against the ground. This systematic approach eliminates potential pathways for vapor intrusion.

Installation and Best Practices for

Longevity

Successful installation of the DELTA-MS UNDERSLAB system is straightforward and critical to its long-term performance. It is important to follow manufacturer guidelines precisely to ensure a continuous barrier.

-

Sub-Base Preparation: The sub-base must be smooth, well-compacted, and free of sharp protrusions that could puncture the membrane. A prepared granular sub-base or an approved leveling layer provides the ideal surface.

-

Placement: The DELTA-MS UNDERSLAB membrane is rolled out directly over the prepared sub-base, with the dimples facing down towards the ground. This instantly establishes the crucial air gap.

-

Overlapping and Sealing: Adjacent rolls must be overlapped correctly according to the system specifications. The overlaps and any penetrations (pipes, conduits) must be securely sealed using manufacturer-specified tapes and mastics to maintain the integrity of the underslab vapor barrier.

-

Edge Detailing: The membrane must be properly sealed at the perimeter walls to connect the floor protection system seamlessly with the wall moisture protection system. This step is essential to prevent moisture from bypassing the floor membrane at the edges of the slab.

By adhering to these steps, construction professionals ensure they are installing a robust, durable, and fully functioning concrete slab moisture barrier that will perform for the life of the structure.

Long-Term Value and Return on Investment (ROI)

Investing in a premium underslab vapor barrier like DELTA-MS UNDERSLAB yields immediate and lasting returns. The cost of installation is a fraction of the expense involved in repairing moisture-damaged concrete, replacing failed flooring, or mitigating mold and air quality issues.

By choosing this advanced system, builders and owners secure a building envelope that is:

-

Healthier: Eliminating the source of moisture migration drastically reduces the risk of mold and mildew, contributing to superior indoor air quality.

-

Durable: Protection of the concrete slab and reinforcing steel ensures the foundation's maximum lifespan.

-

Asset-Protected: The long-term performance of expensive floor finishes is secured, preventing the disruption and financial burden of premature replacement.

DELTA-MS UNDERSLAB represents a commitment to superior construction, delivering the peace of mind that comes with permanent, high-performance moisture control.

Ready to safeguard your foundation and ensure the longevity of your next construction project?

Click Here to explore the full range of DELTA-MS UNDERSLAB products, sizes, and system accessories designed for professional moisture management.

Frequently Asked Questions

What is DELTA-MS UNDERSLAB?

DELTA-MS UNDERSLAB is a highly durable, dimpled high-density polyethylene (HDPE) membrane specifically engineered to function as a premium underslab vapor barrier and moisture management system for concrete slab-on-grade construction.

How does the dimpled design of DELTA-MS UNDERSLAB work as a moisture barrier?

The dimpled structure creates a permanent, continuous air gap, or capillary break, between the soil/sub-base and the concrete slab. This air gap prevents water vapor from wicking upward into the porous concrete, effectively neutralizing hydrostatic pressure and acting as a superior concrete slab moisture barrier.

Is DELTA-MS UNDERSLAB a vapor barrier or a vapor retarder?

DELTA-MS UNDERSLAB is classified as a vapor barrier. Due to its HDPE composition, it has an extremely low perm rating (near zero), which means it significantly exceeds the industry standard required for a true vapor barrier, blocking almost all moisture vapor transmission.

Does this product protect the concrete slab from soil chemicals?

Yes. The high-density polyethylene (HDPE) material used in DELTA-MS UNDERSLAB is highly resistant to the chemicals, salts, and alkalis typically found in soil, ensuring the long-term integrity of the barrier and protecting the concrete foundation.

How is the DELTA-MS UNDERSLAB system sealed?

The system relies on overlapping adjacent rolls and using specific, high-quality seal tapes and mastics to create continuous, airtight seams and details around penetrations (like pipes). This systematic sealing ensures the barrier remains continuous and fully effective.