Posted by Spycor LLC on Sep 9th 2025

For professionals operating in high-stakes environments like mold remediation, asbestos abatement, construction, and disaster restoration, the air they work in isn't just a medium—it's a critical component of safety and liability. The risks are often invisible: microscopic mold spores, carcinogenic asbestos fibers, and respirable crystalline silica dust, all of which can lead to long-term health issues for workers and clients alike. In this reality, the act of maintaining clean, safe air isn't a suggestion or a luxury; it is an absolute non-negotiable requirement dictated by regulatory standards, ethical responsibility, and the fundamental need to protect human health.

This is precisely where the negative air machine emerges as the frontline defense. By creating negative pressure within a contained work zone, these machines act as powerful sentinels, physically preventing hazardous airborne particles from escaping and contaminating adjacent areas. They ensure a controlled environment, pulling polluted air into their sophisticated filtration system to contain the danger where it belongs.

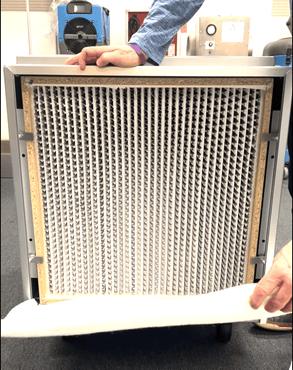

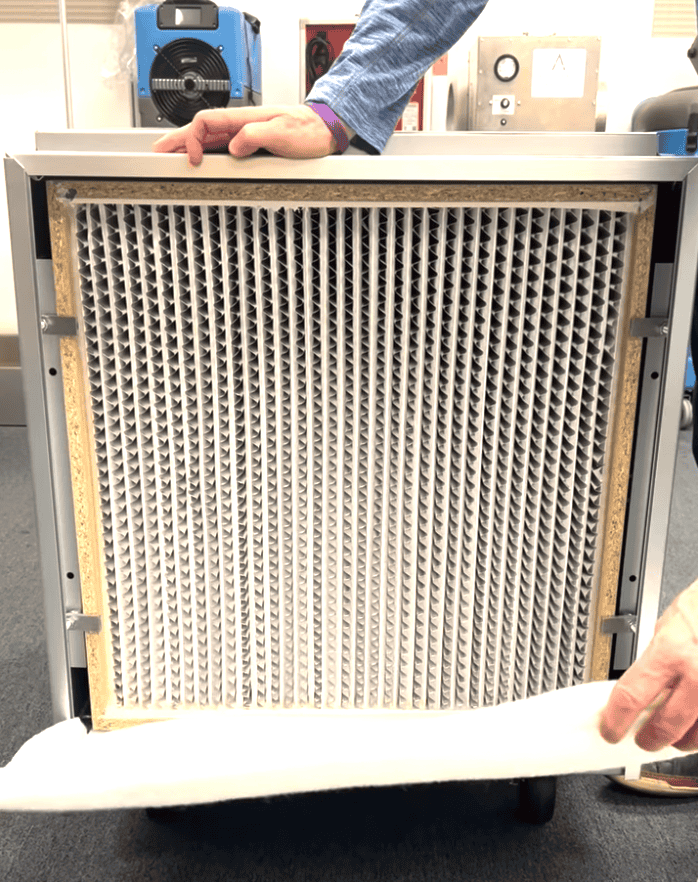

But the machine itself is merely the housing. The true work, the ultimate separation of hazard from safety, hinges on a single, critical component: the Hepa Filter. This isn't just any filter; it's a certified, high-efficiency particle trap engineered to meet a rigorous standard. The quality of this filter determines whether the machine is a life-saving tool or an ineffective piece of equipment. Without a genuine, high-performing HEPA filter, the entire air containment strategy crumbles, exposing everyone to unseen dangers.

What Makes a HEPA Filter "HEPA"?

The term "HEPA" is not a marketing gimmick; it's a filtration standard. A true HEPA filter must be tested and certified to capture at least 99.97% of airborne particles with a size of 0.3 microns. While this might seem like a small number, particles of this size (known as MPPS or Most Penetrating Particle Size) are the most difficult to trap. The effectiveness of HEPA filters against both smaller and larger particles is even higher, thanks to a combination of three filtration mechanisms:

- Impaction: Larger particles traveling in the airstream collide directly with the filter's fibers and become trapped.

- Interception: As smaller particles follow the air's path, they are intercepted by and adhere to the filter's fibers.

- Diffusion: The smallest, most elusive particles move in a random, zig-zag pattern (Brownian motion), increasing their likelihood of colliding with and being captured by the filter fibers.

Choosing the Right HEPA Filter for Your

Negative Air Machine

When selecting a HEPA filter, it's about more than just a name. You need to consider construction, efficiency, and capacity. The industry standard is 99.97% efficiency at 0.3 microns, which is a gold standard for professional applications.

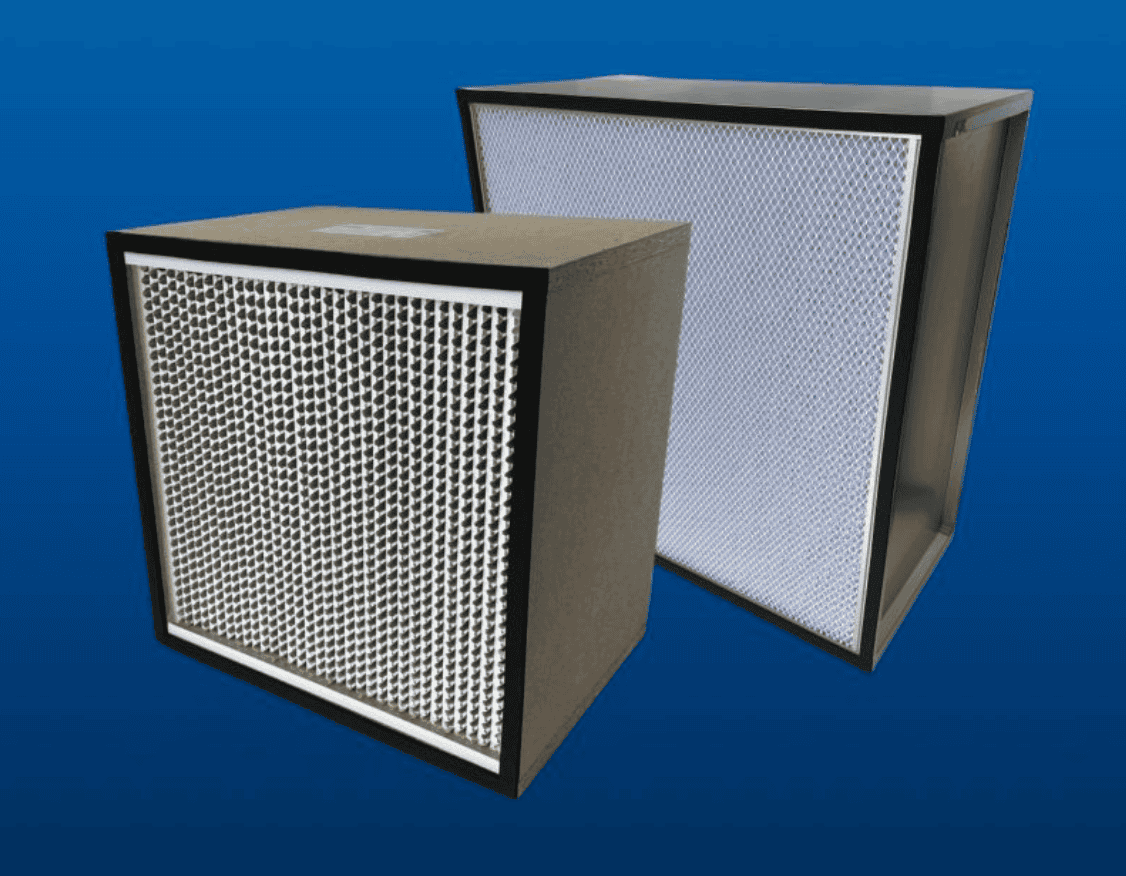

- Wood Frame vs. Metal Frame HEPA Filters: Spycor offers HEPA filters with both wood and metal frames. Wood frames are a traditional, cost-effective option, widely used in various applications. Metal frames, on the other hand, offer superior durability and are often preferred for rugged job sites, with better resistance to moisture and potential damage, ensuring a longer-lasting, secure fit.

- Standard vs. High-Capacity Filters: The physical depth of a filter significantly impacts its lifespan and performance. High-capacity HEPA filters contain a greater volume of filtration media. This increased surface area allows them to capture more contaminants before they become clogged, extending filter life and maintaining optimal airflow for longer periods. This is a critical factor for large-scale projects like commercial renovations or industrial clean-ups.

Essential Performance Tips for Your HEPA

Filtration System

- Don’t Skip the Pre-Filters: The life of your expensive HEPA filter is directly tied to your pre-filters. Negative air machines typically use a two- or three-stage filtration process, with the pre-filter being the first line of defense. These low-cost, disposable filters capture the largest dust and debris, preventing them from clogging the HEPA filter prematurely. Regularly inspecting and changing your pre-filters is the single most important maintenance task to extend the life and effectiveness of your HEPA filter.

- Check the Pressure Gauge: Many professional-grade negative air machines are equipped with a pressure gauge. This simple tool is an invaluable indicator of your HEPA filter's condition. As a filter captures particles, it becomes loaded with contaminants, causing the pressure drop across the filter to increase. A rising reading on the pressure gauge indicates that the filter is nearing the end of its life and needs to be replaced.

- Proper Installation is Key: A high-quality HEPA filter is only as good as its seal. Any gaps or leaks around the filter frame will allow contaminated air to bypass the filter media, rendering the entire system ineffective. Always ensure the filter is correctly seated and the seals are in good condition.

Ready to Find the Right Filter for Your Job?

Choosing the right HEPA filter is a crucial decision that impacts project safety and efficiency. By understanding the technology behind HEPA filtration and following these performance tips, you can ensure your negative air machines are always operating at their best.

For a wide selection of top-quality HEPA filters for your negative air machines, including both wood and metal frame options, visit

Spycor.com

Frequently Asked Questions (FAQs)

How often should I change my HEPA filter?

This depends on the specific application and the level of contaminants. In high-dust environments like construction or mold remediation, a HEPA filter may need to be changed more frequently. The best indicator is the machine’s pressure gauge, or a noticeable drop in airflow.

Can I clean and reuse a HEPA filter?

No. HEPA filters are designed for one-time use and are not washable. Attempting to clean them, whether by washing or vacuuming, will damage the delicate filter media and permanently compromise their efficiency.

Are HEPA filters effective against viruses and bacteria?

Yes, true HEPA filters are highly effective at trapping viruses and bacteria. While these particles are often smaller than 0.3 microns, the diffusion principle of HEPA filtration is particularly effective at capturing them, making these filters essential for healthcare and clean-room applications.

What is a negative air machine used for?

A negative air machine, or air scrubber, is used to create negative pressure in a contained area. This pulls contaminated air from the work zone through a series of filters, containing harmful particles and preventing them from spreading to clean areas. They are critical for preventing cross-contamination on job sites.