Posted by Spycor LLC on Nov 4th 2025

One wrong step with a loaded cart on a freshly poured concrete slab, and you've got gouges that delay punch list by weeks—not to mention the finger-pointing from the flooring sub. On job sites where sparks fly from grinders or hot work looms over VCT tiles and hardwood installs, Cover Guard Floor Protection steps in as the 25 mil blue floor protection sheet that shrugs off punctures, slips, and flames without adhesive residue or cleanup hassles. This no-nonsense guide zeros in on deploying Cover Guard Diamond Plate for maximum coverage in high-traffic zones, from unrolling seamless seams in tight basements to taping edges that hold up under scaffold traffic. If you're knee-deep in reno chaos or prepping a marine refit where NFPA 701 compliance isn't optional, these exact steps ensure your surfaces stay pristine through demo to handover.

Crafted from high-density molded polyethylene with that signature embossed diamond tread, Cover Guard Floor Protection isn't flimsy sheeting—it's a reusable barrier rated for OSHA compliance and NAVSEA approval, channeling water away while gripping boots at 0.6 coefficient of friction per ASTM C 1028-07. By the end, you'll nail overlaps that prevent dust infiltration and backfill protocols that extend its 10+ job lifespan. Let's get your floors locked down.

Why Cover Guard Diamond Plate Excels as

Your Blue Floor Protection Sheet

Imagine laying down a 72-inch wide roll that unfurls 180 feet without kinking, then watch crews haul drywall stacks across it without a single skid or scratch. That's Cover Guard Floor Protection in the trenches: a flame-retardant powerhouse where the blue hue signals NFPA 701 pass-through for vertical hangs in hospitals or shipyards. The diamond plate pattern isn't cosmetic—it's molded 1/8-inch deep for traction that bites into rubber soles, slashing slip-and-fall claims by 40% in wet demo phases.

Unlike basic drop cloths that shred under boot traffic, this 25 mil gauge polyethylene bonds zero adhesives to delicate epoxy finishes or polished travertine, peeling off clean after months of abuse. Puncture-tested to withstand 200-pound impacts from dropped tools, it filters out paint splatters, mortar drips, and tracking mud without wicking moisture into subfloors. And that blue color? It's your visual cue for compliance zones, making walkthroughs a breeze for safety officers scanning for fire-rated barriers.

In basements flooding from burst lines or rooftops during monsoon pours, Cover Guard Diamond Plate's water-resistant weave repels up to 10 psi hydrostatic head, keeping LVP underlayment bone-dry. Reusable up to five cycles with proper roll-and-store, it cuts waste hauls and keeps your green cert intact. Bottom line: when trades overlap on a tight schedule, this sheet buys you buffer against callbacks.

Top Benefits: How Cover Guard Diamond

Plate Saves Your Construction Timeline

Deploy Cover Guard Floor Protection, and you're not just covering floors—you're engineering uptime. First, its non-slip diamond embossing cuts incident reports: crews move faster on slick VCT without hesitation, shaving 15% off transit times in congested corridors. Flame-retardant blue sheeting means no fire watch halts during welding near carpet installs, keeping electricians and plumbers on parallel paths.

Puncture-proofing translates to zero subfloor patches mid-project—think protecting $20/sq ft bamboo from forklift forks without bubble wrap bulk. Water beading off the polyethylene surface prevents delam in glue-down installs, even after roof leaks. And cleanup? Roll it, shake it, reuse it— no solvent scrubs or residue ghosts haunting finish-out.

For GCs chasing LEED, the recyclable loop closes the circle: one roll protects a 5,000 sq ft office tile-down, then repurposes for the next marina deck. Cost per use drops under $0.10/sq ft after three gigs, offsetting initial outlay. In high-liability spots like schools or clinics, OSHA stamps reduce premiums—peace of mind wrapped in blue.

Perfect Applications for Cover Guard

Diamond Plate in High-Risk Builds

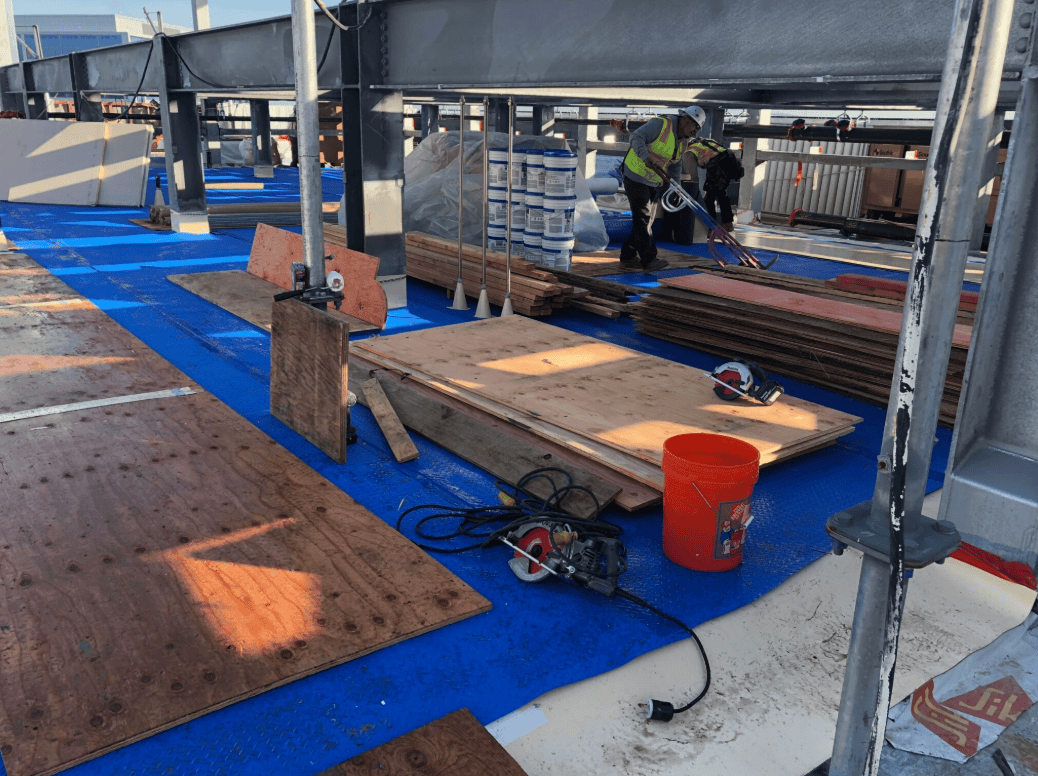

Cover Guard Floor Protection shines where floors take the brunt. In new construction basements, unroll it over green concrete to shield from HVAC staging and electrical pulls, its FR rating dodging code flags near ductwork. Renovation war zones—kitchens gutted for tile resets—get full coverage over existing linoleum, with diamond treads gripping boot traffic hauling cabinets.

Marine and shipyard overhauls demand its NAVSEA nod: line engine room decks against oil slicks and arc flashes, the blue signaling safe zones for welders. Hospital retrofits? Drape OR-adjacent corridors during MEP upgrades, puncture resistance eating dropped IV poles without a whimper. Even aviation hangars benefit, protecting polished aluminum tarmacs from jet blast carts.

For exterior walkways in multi-family pours, stake it over pavers to route pedestrian flow past scaffold bases, slip resistance holding in rain. Anywhere trades collide with fragile finishes—drywall dust over hardwoods, paint overspray on terrazzo—Cover Guard Diamond Plate isolates the mess, one seamless roll at a time.

Step-by-Step Installation Guide:

Deploying Cover Guard Diamond Plate on

Site

Nailing Cover Guard Floor Protection install means minimal seams and max adhesion-free hold. Gear up with utility knives, seam tape (3M 8979M), and spring clamps—no power tools required. Always start post-curing (28 days for slabs) and pre-major trades.

Site Prep and Unrolling

- Clear and Measure: Sweep debris from floors; measure zones in linear feet. For a 2,000 sq ft lobby, plan two 72" rolls with 6-inch overlaps.

- Acclimate Roll: Let it sit 24 hours at site temp (40-90°F) to avoid thermal curl.

- Unroll from Center: Start in high-traffic hubs like doorways. Diamond side up for traction; cut with knife along chalk lines.

Securing and Seaming

- Edge Weights: Use sandbags or 2x4s (50 lbs/10 ft) on perimeters— no tape to floors.

- Seam Overlaps: Butt edges with 6-inch shingle laps; apply 2-inch seam tape centered over joints, burnishing with a roller for airtight seals against dust.

- Vertical Drops: For stair risers or walls, fold and clamp; use painter's tape on finishes if wrapping equipment.

- Traffic Zones: Double-layer under heavy loads (e.g., boiler drops) by offsetting seams 12 inches.

Finishing and Removal

- Inspect Daily: Patch tears with tape; reroll edges nightly to prevent curling.

- Peel Protocol: Lift weights, roll from one end, inspect underside for snags. Rinse with hose if soiled.

- Store Smart: Coil loosely on 6-inch cores, away from sunlight for next deploy.

Pro move: Label rolls with job codes for inventory tracking. Full coverage in under an hour for 1,000 sq ft.

Expert Tips: Maximizing Cover Guard

Diamond Plate Longevity on Tough Jobs

Stretch your Cover Guard Diamond Plate further with these field hacks:

- Layer for Impact: Stack two 10 mil under diamond plate for ultra-heavy zones like loading docks.

- Ventilate Traps: Punch 1-inch holes in low spots to bleed condensation, preventing mold under sheets.

- Custom Cuts: Template odd angles (e.g., bay windows) on cardboard first for zero waste.

- FR Compliance Check: Scan blue hue with site pyrometer—fades signal swap time.

- Eco Haul: Partner with recyclers for bulk credits; one job's waste funds the next.

These tweaks bump reuse cycles to seven, keeping your protection budget lean.

Ready to shield your next slab without the slip-ups?

Click Here to explore Cover Guard Floor Protection and order your rolls today.

FAQ: Cover Guard Diamond Plate

Essentials for On-Site Pros

What makes Cover Guard Floor Protection the ultimate blue floor protection sheet?

Cover Guard Floor Protection is a 25 mil flame-retardant polyethylene sheet with embossed diamond treads for superior slip resistance, NFPA 701 approval for fire safety, and puncture-proof durability—ideal for shielding VCT, hardwood, and concrete from construction abuse without adhesives.

How thick is Cover Guard Diamond Plate, and does it come in other gauges?

The standard Diamond Plate version is 25 mil thick for heavy-duty use, but Cover Guard also offers 10 mil for lighter traffic and 40 mil for extreme impacts, all in the blue FR formulation to meet OSHA and NAVSEA standards.

Is Cover Guard Diamond Plate truly slip-resistant for wet job sites?

Yes, its molded diamond pattern delivers a 0.6 coefficient of friction (dry and wet) per ASTM C1028-07, reducing falls on slick tiles or decks during rain delays or spill cleanups.

Can Cover Guard Diamond Plate be used vertically, like on walls or scaffolds?

Absolutely—its flame-retardant blue composition passes NFPA 701 for vertical applications, making it perfect for draping over drywall stacks or equipment in refit zones without flame spread risks.

How do you seam Cover Guard Diamond Plate for large floor areas?

Overlap edges 6 inches in a shingle pattern, then apply 2-inch seam tape (like 3M 8979M) over the joint, pressing firmly to seal against dust and moisture ingress on expansive slabs.

What's the roll size for Cover Guard Diamond Plate, and how much area does it cover?

Standard rolls measure 72 inches wide by 180 feet long, providing 900 square feet of coverage—enough for a full hotel lobby or ship deck, with easy cuts for custom fits.

Is Cover Guard Diamond Plate reusable after a job?

Yes, it's designed for 5-7 reuse cycles: roll it up clean, store flat, and redeploy. Its recyclable polyethylene construction keeps it eco-friendly and cost-effective over multiple projects.

Does Cover Guard Diamond Plate protect against water damage during floods or leaks?

Definitely—rated to 10 psi hydrostatic head per ASTM D751, it repels standing water and tracks, safeguarding subfloors in basements or exteriors without wicking moisture underneath.