Posted by Spycor LLC on Dec 2nd 2025

In large-scale commercial, construction, and remediation environments, airborne contamination presents a constant triple threat: a risk to worker health, a liability for regulatory non-compliance, and a potential cost driver through job site spread. Standard ventilation systems are simply not engineered to handle the microscopic, hazardous particulate matter generated by activities like demolition, sanding, or mold remediation.

To effectively manage these risks, professionals rely on specialized air filtration equipment designed for high-volume, critical air quality control: the industrial negative air machine and the portable air scrubber. Understanding the nuanced function of each is crucial for selecting the right tool to achieve complete containment and absolute safety.

The Core Difference: Containment vs.

Recirculation

Although often grouped together, the industrial negative air machine and the portable air scrubber serve distinct, though sometimes overlapping, primary functions. Choosing incorrectly can compromise job site safety and regulatory compliance.

Negative Air Machine: Containment and Negative Pressure

The industrial negative air machine is built specifically for containment. Its core function is to create a controlled negative pressure environment within a sealed work zone (e.g., during asbestos abatement or hazardous material removal).

This is achieved by continually drawing air out of the confined space and exhausting the filtered air outside the building or far away from clean zones via ducting. Because air is constantly being extracted, the pressure inside the room drops lower than the pressure in adjacent areas. This pressure differential ensures that when a door or seal is breached, air is always drawn into the contained space rather than allowing contaminated air to escape.

Key Applications:

-

Asbestos/Lead Abatement: Preventing hazardous fibers from spreading to other parts of the building.

-

Infection Control: Creating isolation wards in healthcare settings.

-

Critical Mold Remediation: Ensuring mold spores cannot migrate during removal.

Portable Air Scrubber: Air Quality Recirculation

The portable air scrubber, often interchangeable with a "commercial air purifier," is designed for recirculation. It draws air in, passes it through a multi-stage filtration system, and then blows the clean, filtered air back into the same space.

Air scrubbers are primarily used to clean the air within a general work area where contamination risk is high but complete containment is not the critical priority. They excel at reducing ambient construction dust control, filtering smoke and odors during fire/water restoration, or cleaning the air after demolition is complete. They improve indoor air quality (IAQ) for workers but do not create the critical pressure differential necessary for regulatory-mandated containment.

Key Features of Professional Air Filtration

Equipment

For high-stakes industrial use, the efficacy of any air filtration equipment is determined by its technical specifications and capacity to meet rigorous standards.

The HEPA Filtration Standard

The most critical component of any modern industrial negative air machine or air scrubber is the High-Efficiency Particulate Air (HEPA) filter. To be considered HEPA, a filter must meet or exceed a proven filtration efficiency standard: 99.97% removal of airborne particles down to 0.3 microns in diameter.

The filtration process itself is typically multi-stage to protect the expensive HEPA filter and prolong its life:

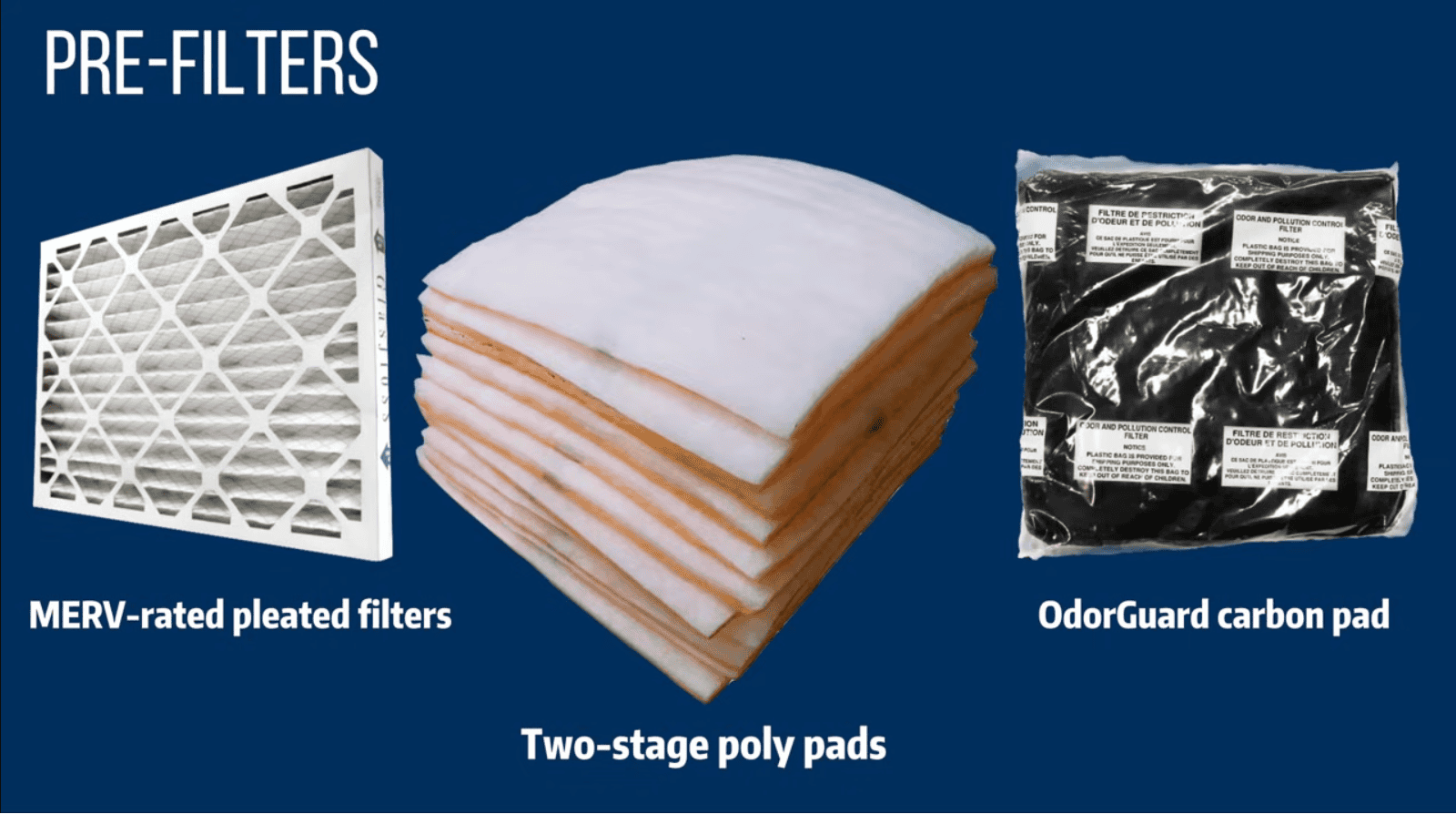

-

Pre-Filters: Capture large particles (e.g., construction debris, coarse dust) to prevent premature clogging of downstream filters.

-

Primary/Secondary Filters: Trap medium-sized particles.

-

HEPA Filter: The final barrier, capturing microscopic contaminants like mold spores, silica dust, asbestos fibers, and even bacteria.

-

Optional Activated Carbon Filters: Used for the adsorption of gaseous contaminants, odors, and Volatile Organic Compounds (VOCs) from paint, solvents, or chemicals.

Critical Applications & Compliance

The primary differentiator for the industrial negative air machine is its role in mandated safety and compliance across several key industrial sectors.

Mold Remediation and Asbestos Abatement

These projects are legally required to employ containment protocols to protect public health. Using a certified industrial negative air machine is non-negotiable. The machine creates a sealed environment, ensuring that highly toxic asbestos abatement fibers or allergenic mold remediation spores are captured by the HEPA filter and exhausted safely, preventing cross-contamination of clean zones. Compliance hinges on maintaining the pressure differential, and professional-grade machines often feature audible or visual alarms for monitoring filter loading and pressure stability.

Commercial Construction & Renovation

While full negative air machine containment may not always be required, construction dust control is critical. Fine particulate matter (e.g., silica, drywall dust) is a recognized respiratory hazard and a major source of cleanup costs. Portable air scrubbers are routinely deployed to:

-

Source-capture dust at the point of generation (e.g., near sanding stations).

-

Recirculate and clean ambient air, improving air quality for tradespeople.

-

Filter out odors and VOCs from materials like adhesives and sealants before occupancy.

The presence of high-grade air filtration equipment demonstrates a commitment to worker safety and project quality, leading to smoother inspections and cleaner handovers.

Maximizing Efficiency and Longevity

Investing in an industrial negative air machine is a long-term capital decision. Maximizing its value depends on proper usage and maintenance.

-

Monitor Filter Pressure: Professional units feature filter loading indicator lights or gauges (manometers). As the filters load with contaminants, the pressure drop increases. Operating the machine past the recommended pressure differential point reduces CFM drastically, compromising containment and risking motor burnout. Change filters immediately upon indication.

-

Proper Ducting and Sealing: Air leaks around ducting, windows, or doors will neutralize the negative pressure effect. Ensure all seals are airtight, and use heavy-duty, reinforced ducting to maintain optimal airflow to the exhaust point.

-

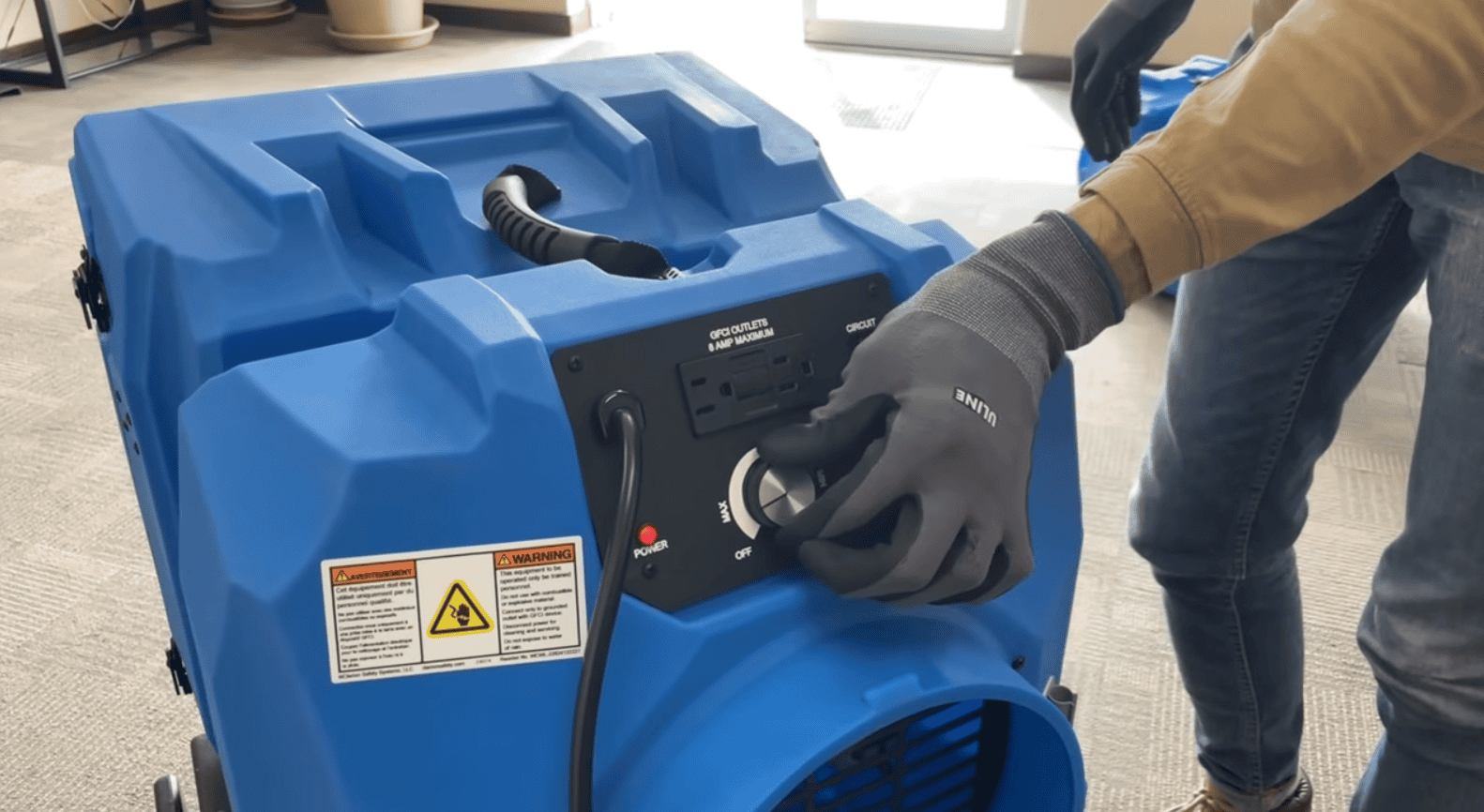

Variable Speed Control: Many quality air filtration equipment models feature variable speed blowers. This allows for precise tuning of the ACH to meet specific regulatory requirements or to save energy in smaller spaces where maximum CFM is unnecessary.

The choice of industrial negative air machine and portable air scrubber is the single most important decision in any project where air quality, regulatory compliance, and health protection are non-negotiable. Investing in professional, certified HEPA filtration equipment is not merely a cost of doing business—it is the ultimate defense against liability and the foundation of a safe, compliant operation.

Order Now at spycor.com to secure the best air filtration equipment for your toughest containment challenges.

Frequently Asked Questions (FAQ)

1. How often should the HEPA filter be replaced?

The HEPA filter replacement schedule depends entirely on usage and the contaminant level. The primary indicator is the pressure differential gauge on the machine. Typically, pre-filters should be replaced frequently (weekly or daily on high-dust jobs) to protect the expensive HEPA filter, which may last for several months or even a year under light use.

2. Is a portable air scrubber the same as a HEPA vacuum?

No. A HEPA vacuum is a handheld tool designed for surface cleanup and localized vacuuming. An air scrubber is a high-volume air filtration equipment unit designed to clean the air in an entire room, cycling the air multiple times per hour to reduce airborne particulate concentration.

3. How do I calculate the CFM needed for my project?

The required CFM is determined by calculating the cubic volume of your containment area and multiplying it by the mandated Air Changes per Hour (ACH), then dividing by 60. For example, a 10,000 cubic foot room requiring 6 ACH needs a machine rated for $60,000 / 60 = 1,000 \space CFM$.

4. What are the consequences of not using a negative air machine for asbestos abatement?

Failure to use an industrial negative air machine during asbestos abatement can lead to the widespread contamination of surrounding areas. This is a severe violation of OSHA and EPA regulations, resulting in significant fines, project stoppages, costly mandatory decontamination of adjacent spaces, and potential litigation related to public health risk.