Posted by Spycor LLC on Sep 22nd 2025

Clean air is a cornerstone of safe, efficient operations in industries like pharmaceuticals, healthcare, and electronics manufacturing. Contaminants as small as 0.3 microns can disrupt production, compromise health, or violate strict regulations. Spycor HEPA filters, engineered for 99.97% efficiency at this critical particle size, deliver reliable solutions for cleanrooms, labs, and HVAC systems. This guide dives into HEPA filter efficiency, industry standards, and how Spycor’s high-performance filters ensure cleaner air in 2025’s demanding environments.

Whether you’re upgrading a hospital’s HVAC system or maintaining an ISO-compliant cleanroom, understanding HEPA technology helps you make informed decisions. We’ll cover how these filters work, their compliance with rigorous standards, and why Spycor’s customizable designs are trusted across industries.

What Are HEPA Filters and How Do They

Work?

HEPA filters, or High-Efficiency Particulate Air filters, are designed to capture tiny particles that standard filters miss. Developed in the 1940s to contain radioactive dust, they’re now essential in settings requiring pristine air. A HEPA filter uses a dense web of fibers—typically fiberglass—to trap contaminants through three mechanisms:

- Interception: Particles adhere to fibers as air flows past.

- Impaction: Larger particles collide with fibers and stick.

- Diffusion: Ultrafine particles move erratically, increasing capture.

This process removes dust, pollen, bacteria, viruses, and some volatile organic compounds (VOCs). With indoor air quality linked to health risks like respiratory issues or reduced cognitive function (up to 15% in poor conditions), HEPA filters are critical for workplaces and sensitive facilities.

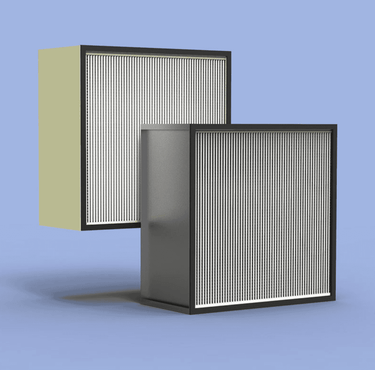

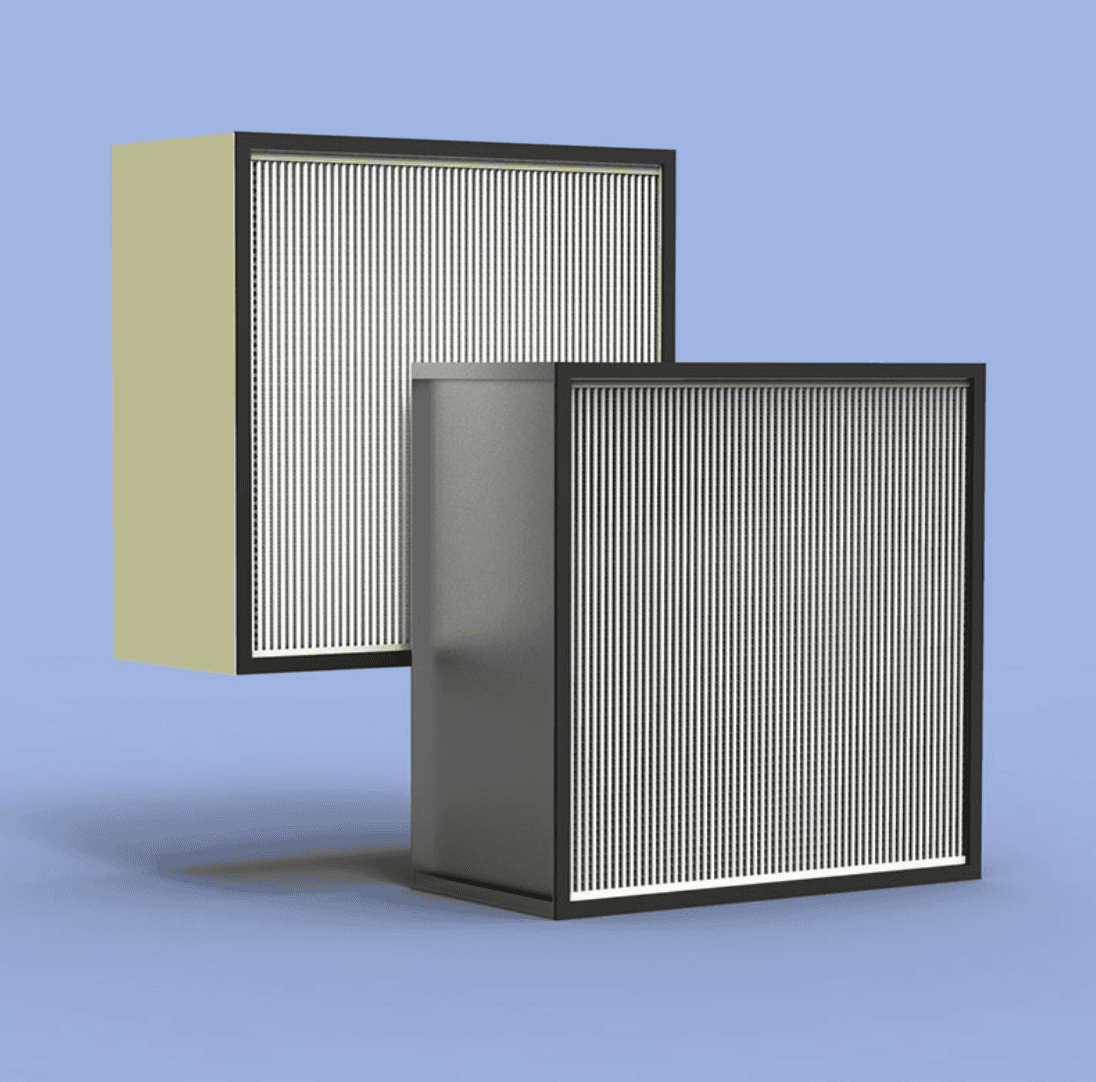

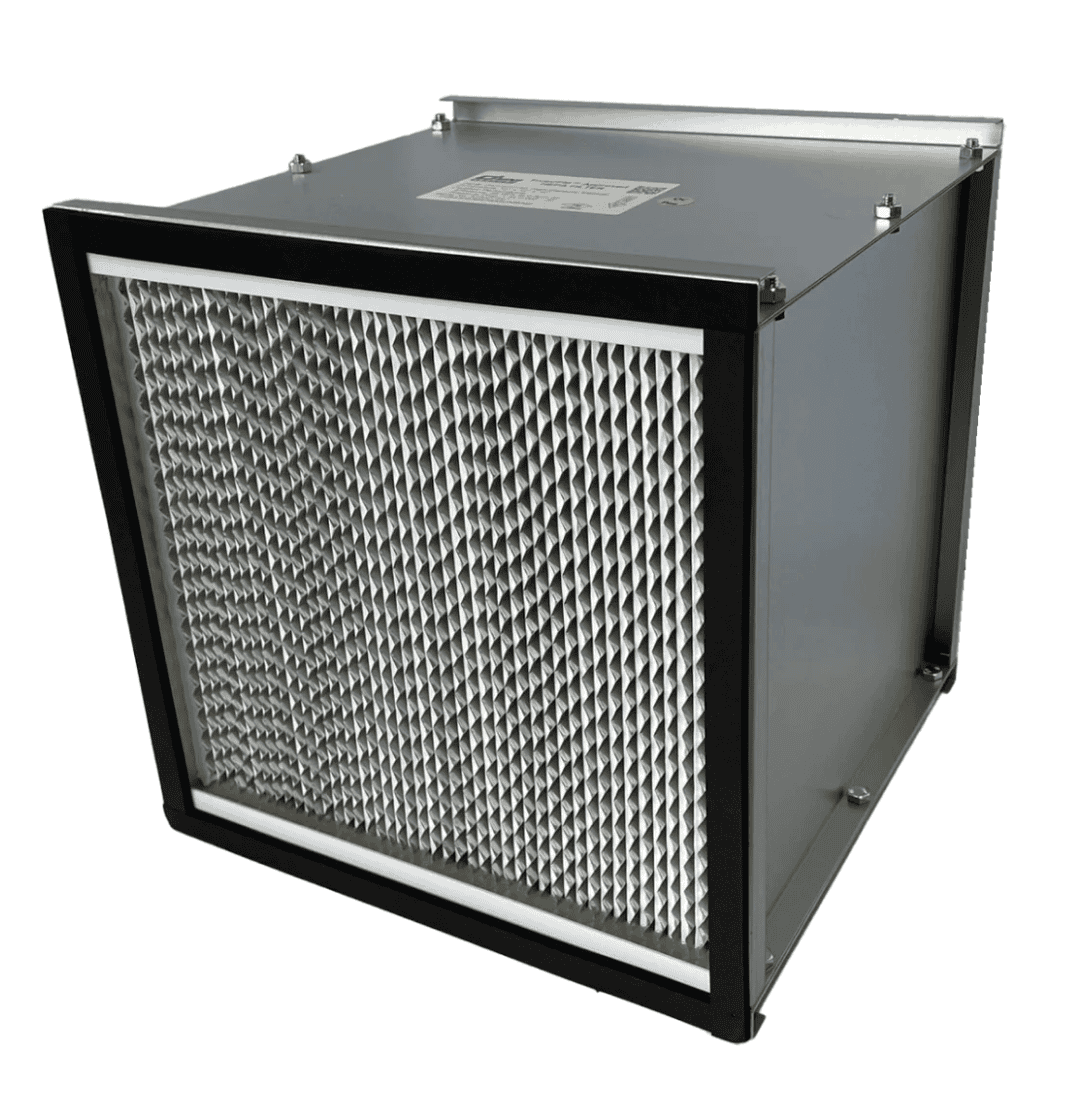

Spycor HEPA filters meet true HEPA standards, capturing 99.97% of 0.3-micron particles. Built with durable galvanized steel or aluminum frames and available in custom sizes like 24x24x12 inches, they integrate seamlessly into cleanrooms, labs, and HVAC systems. Their high airflow capacity (up to 2470 CFM) ensures performance without sacrificing efficiency.

Understanding HEPA Filter Efficiency

Ratings

Efficiency is what makes HEPA filters exceptional. The U.S. Department of Energy (DOE) defines true HEPA as capturing 99.97% of particles at 0.3 microns—the most penetrating particle size (MPPS), where filtration is least effective. This distinguishes true HEPA from “HEPA-like” filters, which may only achieve 95-99% efficiency and lack rigorous testing.

Compared to standard filters rated on the MERV scale (1-16), true HEPA filters align with MERV 17 or higher, making them ideal for environments where even a 0.03% particle leak could cause issues, such as pharmaceutical labs. Spycor HEPA filters are individually tested to confirm this 99.97% efficiency, ensuring reliable performance.

Their deep-pleat design maximizes surface area, allowing high airflow (55–2470 CFM) with a low pressure drop (below 1.0 inch w.g.). This reduces energy use by 15-25% compared to less efficient filters, a key benefit for large facilities. For ultrafine particles below 0.1 microns, Spycor’s enhanced diffusion capture keeps air pristine, while Clean Air Delivery Rate (CADR) metrics confirm their ability to handle high air volumes.

Industry Standards for HEPA Filters

Compliance with industry standards ensures HEPA filters deliver promised results. The DOE requires 99.97% efficiency at 0.3 microns for true HEPA status. Globally, EN 1822:2019 and ISO 29463 standards classify filters from E11 (≥95% at MPPS) to U17 (≥99.999995%). For example, H14 filters capture ≥99.995% at 0.1-0.2 microns, ideal for ultra-clean settings.

Cleanrooms adhere to ISO 14644-1, which limits particle counts for ISO 1-9 classes. ASHRAE guidelines recommend MERV 17+ (HEPA) filters for healthcare to reduce infection risks. In 2025, standards like EN 1822 also prioritize energy efficiency, rewarding low-pressure-drop filters to support sustainability.

OSHA and FDA regulations mandate HEPA use in food processing, biotech, and healthcare to prevent contamination. Spycor HEPA filters meet DOE, ISO, and EN standards, with leak testing per IEST-RP-CC001 to ensure no contaminants bypass the filter. This makes them a trusted choice for compliance-driven industries.

Why Choose Spycor HEPA Filters?

Spycor HEPA filters are built for performance and versatility, offering:

- Top Efficiency: 99.97% capture at 0.3 microns for clean air in sensitive settings.

- Custom Sizing: Options like 24x24x12 inches fit any HVAC or cleanroom system.

- Durable Frames: Galvanized steel or aluminum resists corrosion, with high-temperature models up to 500°F.

- Energy Efficiency: Low pressure drop saves 20-30% on utility costs.

- High Airflow: CFM ratings up to 2470 support large-scale operations.

Each filter is individually tested for reliability, making Spycor a top choice for industrial applications. Their deep-pleat design extends lifespan (6-12 months), reducing maintenance costs and aligning with 2025’s focus on sustainable filtration.

Benefits of Spycor HEPA Filters for Air

Quality

Spycor HEPA filters deliver tangible advantages:

- Health Protection: Capture 99.97% of allergens, bacteria, and viruses, reducing respiratory risks and infections in healthcare settings.

- Cost Savings: Low pressure drop cuts HVAC energy use by 15-25%, saving thousands annually in large facilities.

- Durability: Robust frames withstand humidity and chemicals, ideal for harsh environments.

- Compliance: Meet DOE, ISO, and FDA standards, ensuring audit-ready performance.

- Productivity Gains: Cleaner air boosts focus and cuts sick days, with studies showing 10-15% cognitive improvements.

Spycor’s eco-friendly designs, free of harmful chemicals, support green initiatives while maintaining top performance.

Applications Across Industries

Spycor HEPA filters excel in diverse sectors:

- Pharmaceuticals: Maintain sterile ISO 5-8 cleanrooms, meeting FDA cGMP standards.

- Healthcare: Protect operating rooms and isolation units from pathogens.

- Electronics: Prevent dust-related defects in microchip production.

- Food Processing: Ensure HACCP compliance by blocking mold and bacteria.

- Commercial HVAC: Enhance air quality in offices, schools, and retail spaces.

Their customizable solutions deliver precision for any application, from labs to large commercial buildings.

Maintenance Tips for Peak HEPA Performance

To keep Spycor HEPA filters performing optimally:

- Replace Every 6-12 Months: Monitor pressure drop to avoid clogs.

- Inspect Regularly: Check for tears or leaks to maintain efficiency.

- Use Pre-Filters: Capture larger particles to extend HEPA life.

- Ensure Tight Seals: Prevent air bypass during installation.

- Test Airflow: Verify system performance after filter changes.

Spycor HEPA filters combine efficiency, compliance, and durability to deliver superior air quality. From meeting stringent industry standards to reducing energy costs, they’re built for today’s toughest challenges.

Upgrade your facility’s air quality now. CLICK HERE to explore our range and request a quote. Contact our team for tailored solutions—cleaner air starts here!

FAQ

What’s the difference between true HEPA and HEPA-like filters?

True HEPA filters capture 99.97% of 0.3-micron particles with DOE certification, while HEPA-like filters may only reach 95-99% and lack testing.

How do Spycor HEPA filters save energy?

Their low pressure drop (below 1.0 inch w.g.) reduces HVAC fan workload, cutting energy use by up to 25%.

Are Spycor HEPA filters suitable for high-temperature environments?

Yes, select models operate up to 500°F, ideal for industrial processes.

What standards do Spycor HEPA filters meet?

They comply with DOE, ISO 14644, and EN 1822 standards for cleanroom and industrial use.

How do I choose the right HEPA filter size?

Match your system’s dimensions and airflow needs; Spycor offers custom sizes like 24x24x12 inches.