Posted by Spycor LLC on Feb 2nd 2026

Healthcare construction presents a unique set of challenges, where the quality of the air is as critical as the structural integrity of the building. For commercial contractors operating in this specialized sector, understanding and implementing robust air filtration protocols isn't just a best practice—it's a non-negotiable requirement for patient safety, regulatory compliance, and project success. This guide cuts through the noise to provide actionable insights on selecting the right HEPA filters, ensuring your projects meet stringent Infection Control Risk Assessment (ICRA) standards and maintain pristine air quality.

The Imperative of Clean Air in Healthcare Environments

Construction and renovation within active healthcare facilities introduce significant risks. Dust, mold spores, and other airborne particulates, including dangerous pathogens like Aspergillus, can spread rapidly, compromising sterile environments and endangering immunocompromised patients. This is precisely why HEPA filters for construction are not merely an accessory but a fundamental tool in your arsenal. They are the frontline defense against airborne contaminants, ensuring that your work areas are properly contained and that ambient air in occupied patient zones remains safe.

Ignoring these protocols can lead to severe consequences, including:

-

Project Delays and Shutdowns: Breaches in infection control can force immediate cessation of work.

-

Reputational Damage: Negative publicity can impact future bids and client trust.

-

Legal and Financial Penalties: Non-compliance with ICRA standards can result in hefty fines and lawsuits.

For commercial contractors specializing in healthcare and other specialized technical sectors, protecting the health of occupants and the integrity of the facility is paramount. This starts with a deep understanding of air filtration technology, specifically HEPA filters.

Understanding ICRA: Your Blueprint for Air Quality Compliance

The Infection Control Risk Assessment (ICRA) is the cornerstone of safe healthcare construction. It categorizes construction activities based on their potential risk to patients and mandates specific control measures. For most critical healthcare renovations, you will be operating under ICRA Class III or IV, which demand the highest level of air quality control.

Key requirements under these classes often include:

-

Negative Air Pressure: Maintaining a lower air pressure within the construction zone compared to adjacent areas, preventing contaminated air from escaping.

-

HEPA Filtration: Utilizing air-scrubbing equipment equipped with HEPA filters to capture microscopic particles.

-

Continuous Monitoring: Ensuring containment integrity and filter efficacy throughout the project.

This is where the right HEPA filters for construction become essential. They are the heart of your negative air machines, air scrubbers, and specialized ventilation systems, directly impacting your ability to meet these critical ICRA guidelines.

The Science Behind HEPA: Why 99.97% Matters

HEPA stands for High-Efficiency Particulate Air. A true HEPA filter is certified to capture at least 99.97% of airborne particles 0.3 micrometers (µm) in diameter. While 0.3 µm might seem arbitrarily specific, it represents the Most Penetrating Particle Size (MPPS) – the size that is hardest for a filter to catch. Particles larger or smaller than 0.3 µm are actually easier for a HEPA filter to capture due to different physical mechanisms (impaction, interception, diffusion).

This incredible efficiency is critical for:

-

Pathogen Containment: Capturing bacteria, mold spores (including Aspergillus), and even some viruses that may piggyback on larger dust particles.

-

Allergen Removal: Protecting sensitive patients from common construction allergens.

-

Dust Control: Preventing fine construction dust from migrating into patient care areas, safeguarding equipment and health.

When sourcing HEPA filters, always confirm their 99.97% efficiency rating at 0.3 microns. This is the benchmark for true HEPA performance, and anything less puts your project and reputation at risk.

Selecting Your HEPA Filters: Key Considerations for Commercial Contractors

Choosing the correct HEPA filters involves more than just picking a size. For commercial contractors, especially those focused on hospital renovation dust control, several factors come into play:

1. Filter Dimensions: Matching Your Equipment

The most common size for portable negative air machines and air scrubbers on construction sites is 24x24x11.5 inches. This is a standard dimension that ensures compatibility with a wide range of industrial-grade equipment designed for high-volume air movement. Ensuring your filters precisely match your equipment's specifications prevents bypass leakage, where air circumvents the filter entirely, rendering your containment efforts useless.

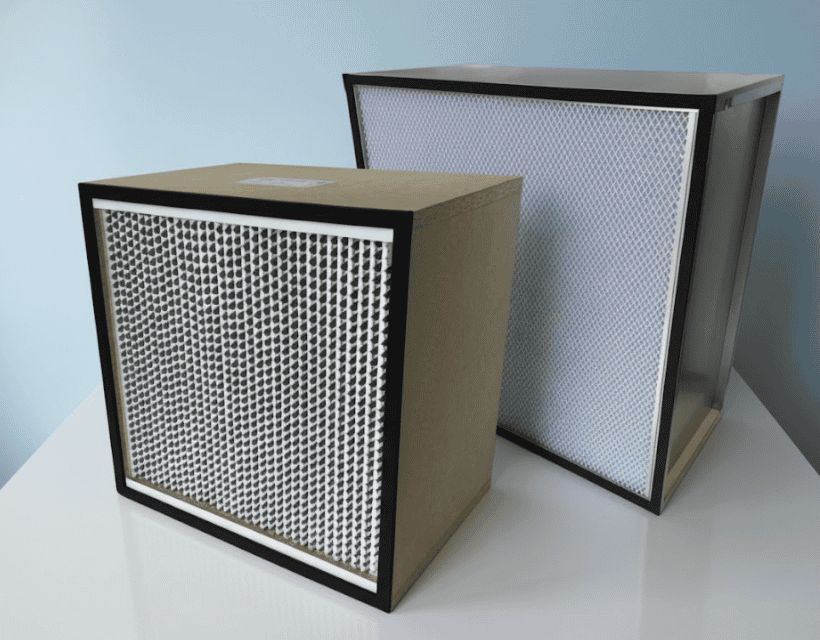

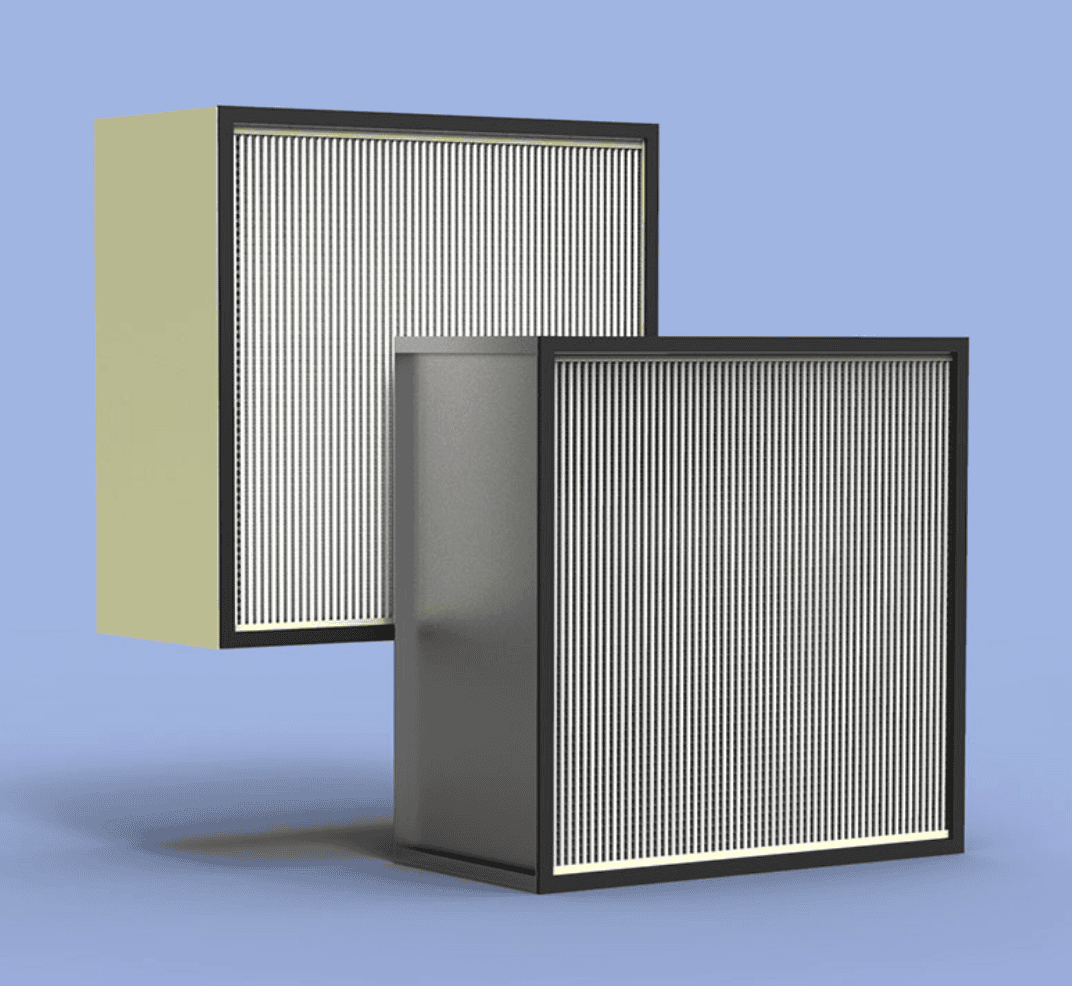

2. Frame Type: Particle Board vs. Metal

-

Particle Board Frame (Cost-Effective for Temporary Use): Filters with particle board frames are an excellent choice for construction environments. They offer a highly effective filtration solution at a more economical price point. For temporary installations in negative air machines or air scrubbers, where filters are regularly changed due as they become saturated with construction dust, the particle board frame provides sufficient structural integrity without the added cost of a metal frame. This allows contractors to manage project budgets effectively while still meeting stringent filtration requirements.

-

Metal Frame (Durability for Permanent Installations): While particle board is often suitable for temporary construction, metal frames offer superior durability and resistance to moisture. These are typically preferred for permanent HVAC installations or environments with high humidity where the filter will remain in place for extended periods. For most construction dust control applications, where filters are changed frequently, particle board frames offer the ideal balance of performance and cost.

3. Standard vs. High Capacity: Balancing Lifespan and Airflow

-

Standard-Capacity HEPA Filters: These are highly effective for capturing fine particles and are a reliable choice for most hospital renovation dust control scenarios. They offer a good balance of filtration efficiency and lifespan, making them a go-to for daily operations.

-

High-Capacity HEPA Filters: For extremely dusty environments or applications where filter changes need to be minimized, high-capacity filters offer extended service life. Their deeper pleats and greater surface area allow them to hold more particulate matter before airflow is significantly restricted. Consider these for demolition phases or projects with exceptionally high dust generation.

4. Pre-Filters: Extending HEPA Lifespan

Never underestimate the power of a good pre-filter. These coarser filters capture larger particles (like drywall dust, concrete dust, and larger debris) before they reach the HEPA filter. This dramatically extends the life of your more expensive HEPA units, saving you money and reducing the frequency of filter changes. Always ensure your air scrubbers are equipped with appropriate pre-filters and that they are changed regularly.

Implementing Your HEPA Filtration Strategy

Once you've selected the right HEPA filters, effective implementation is key:

-

Negative Air Machines: Deploy these strategically to create directional airflow, ensuring air moves from clean areas into the contaminated construction zone. Equip them with the appropriate ICRA compliant negative air machines using your chosen HEPA filters.

-

Containment Barriers: Use robust physical barriers (e.g., poly sheeting, hard walls) to seal off the construction zone completely.

-

Regular Monitoring: Use manometer gauges to monitor differential pressure and ensure negative pressure is maintained. Inspect filters regularly for visible loading and replace them according to manufacturer guidelines or when airflow significantly decreases.

-

Proper Disposal: Treat used HEPA filters as contaminated waste and dispose of them according to facility protocols and local regulations.

Maximizing Your Investment: Bulk Purchases and Reliable Supply

For commercial contractors managing multiple projects or large-scale renovations, securing a consistent and reliable supply of HEPA filters is crucial. Unforeseen delays due to filter shortages can be costly.

Consider:

-

Buying in Bulk: Purchasing HEPA filter bulk quantities not only ensures availability but also typically offers significant cost savings. This is a smart procurement strategy for ongoing projects.

-

Reliable Supplier: Partner with a supplier who understands the demands of commercial construction and can provide timely delivery and expert support. Your supplier should be able to advise on product specifications and help you manage inventory.

Secure Your Project's Air Quality: Choose the Right HEPA Filters Today

For commercial contractors in healthcare and specialized technical sectors, precision in air quality management is not a luxury—it's a necessity. The integrity of your projects and the safety of the environments you create depend on it. Don't compromise on your air filtration strategy.

Ensure your next healthcare construction project meets the highest ICRA standards and protects every occupant.

Browse our extensive selection of 99.97% efficient HEPA filters, including the essential 24x24x11.5 size, designed for superior performance in demanding commercial environments.

Frequently Asked Questions (FAQ)

What is the most common size for HEPA filters used in construction air scrubbers?

The most common and industry-standard size is 24x24x11.5 inches. This fits most portable negative air machines and air scrubbers designed for commercial construction.

How often should HEPA filters be changed on a construction site?

The change frequency depends on the dust load, the specific phase of construction (e.g., demolition vs. finishing), and the capacity of the filter. It's crucial to monitor airflow and pressure drop across the filter. A significant reduction in airflow or an increase in differential pressure indicates it's time for a change. Regular inspection and consistent pre-filter changes can extend the life of your HEPA filters.

Are particle board frame HEPA filters suitable for healthcare construction? Yes, particle board frame HEPA filters are widely used and highly suitable for temporary construction applications, especially in negative air machines and air scrubbers. They provide excellent filtration efficiency at a cost-effective price point, making them ideal for situations where filters are frequently replaced due to dust loading.

Can I use any HEPA filter for ICRA compliance?

No. For true ICRA compliance, you must use certified HEPA filters with a minimum efficiency of 99.97% at 0.3 microns. Always verify the specifications and ensure the filters are compatible with your ICRA compliant negative air machines.

Why is negative air pressure important in healthcare construction?

Negative air pressure creates a controlled airflow direction, drawing air from clean areas into the construction zone. This prevents contaminated air, dust, and pathogens from escaping the work area and migrating into critical patient care or sterile environments, thereby maintaining infection control.