Posted by Spycor LLC on Sep 24th 2025

As airborne contaminants continue to pose significant health risks in modern workspaces, understanding the nuances between specialized filtration systems becomes essential for professionals in construction, restoration, and healthcare. Whether you're managing a hospital renovation or tackling mold remediation in a commercial building, the choice between a negative air machine and an air purifier can dramatically impact air quality, safety compliance, and project efficiency. In this comprehensive guide, we'll dive deep into the mechanics, applications, and key differences of these two powerhouse technologies, helping you make an informed decision tailored to your specific environment.

Understanding Negative Air Machines: The

Containment Powerhouses

Negative air machines, often referred to as HEPA air scrubbers or negative pressure units, are engineered to create controlled environments where airborne pollutants are isolated and removed. These devices work by generating negative pressure within a sealed space, drawing in contaminated air through high-efficiency particulate air (HEPA) filters, and then exhausting the cleaned air outside or recirculating it safely. This process is crucial in scenarios where preventing the spread of dust, mold spores, asbestos fibers, or lead particles is paramount.

At their core, negative air machines utilize a fan system to pull air into the unit at high volumes, typically measured in cubic feet per minute (CFM). For instance, models capable of 1,000 to 2,000 CFM can achieve multiple air changes per hour in large areas, ensuring thorough filtration. The HEPA filter, rated at 99.97% efficiency for particles as small as 0.3 microns, captures microscopic contaminants that standard filters miss. Optional pre-filters extend the life of the HEPA by trapping larger debris, while carbon filters can add basic odor control.

Consider the science behind negative pressure: By maintaining lower air pressure inside the containment area compared to surrounding spaces, any potential leaks draw clean air in rather than allowing polluted air out. This principle aligns with Infection Control Risk Assessment (ICRA) guidelines in healthcare settings, where protecting vulnerable patients from construction dust is non-negotiable. In abatement projects, such as asbestos removal, these machines comply with OSHA standards, reducing worker exposure and environmental hazards.

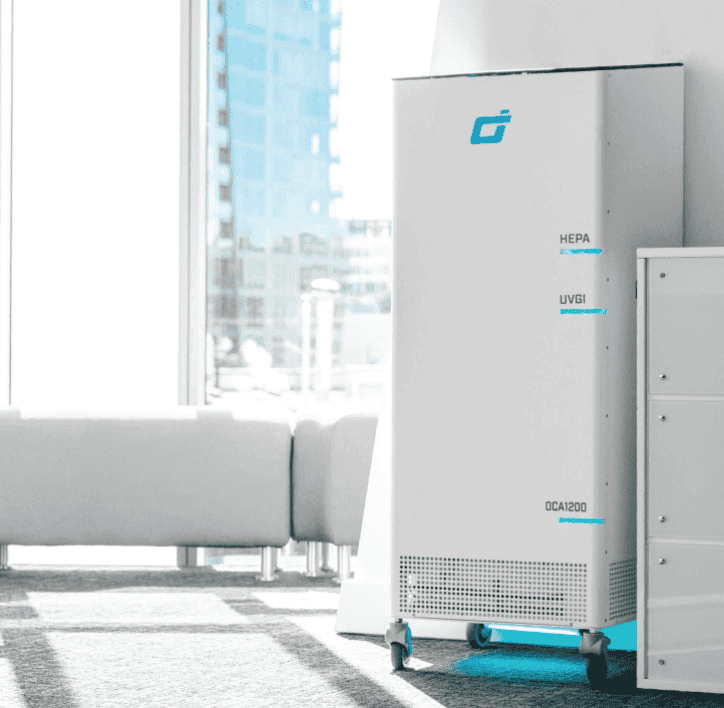

Popular models highlight the versatility of negative air machines. The OMNIAIRE OA2000V, for example, offers variable speed control up to 2,000 CFM, making it ideal for mold and asbestos abatement in confined spaces. Its aircraft-grade aluminum housing ensures durability and easy sanitization, with an optional UV module for added germicidal protection. Similarly, the OA2200UL provides dual speeds (1,000/2,000 CFM) and a robust 24" x 24" x 12" HEPA filter, suited for large-scale demolition. These units often feature silicone-sealed seams to prevent filter bypass, industrial casters for mobility, and thermal overload protection for safe operation.

In practical terms, negative air machines excel in high-stakes environments like hospitals during renovations, where they prevent cross-contamination between work zones and patient areas. For restoration after floods or fires, they contain soot and mold, accelerating cleanup while minimizing secondary damage. Their industrial build makes them resilient in dusty job sites, but they require regular filter changes—typically every 500-1,000 hours—to maintain peak performance.

Exploring Air Purifiers for Odor, VOC, and

Bio Contaminants: The Molecular

Neutralizers

Shifting focus to air purifiers designed specifically for odor, volatile organic compounds (VOCs), and biological agents, these units prioritize chemical and gaseous pollutant destruction over sheer particulate capture. Unlike traditional consumer air purifiers, these professional-grade systems employ advanced oxidation technologies, such as ionized hydroperoxides, to break down contaminants at the molecular level. This makes them indispensable for post-remediation cleanup or ongoing air quality maintenance in occupied spaces.

The process involves generating oxidizer plasma that reacts with odors, VOCs (like formaldehyde from paints or ammonia from cleaners), and biohazards (bacteria, viruses, mold byproducts). This plasma not only purifies the air passing through the unit but also continues to sanitize surfaces after release, providing a comprehensive decontamination effect. These purifiers are often compact and portable, with low noise levels suitable for hospitals, offices, or homes without disrupting daily activities.

Educationally, let's break down VOC removal: Volatile organic compounds are gaseous pollutants that evaporate from materials like adhesives and solvents, contributing to sick building syndrome. Bio contaminants, including viruses and bacteria, thrive in humid environments, exacerbating respiratory issues. Air purifiers target these by oxidizing their molecular structures, rendering them harmless. This contrasts with mechanical filtration, offering a proactive approach to air sanitation.

In use cases, these purifiers shine in fire and flood restoration, where lingering smells can delay occupancy. They're also vital in healthcare for controlling bioaerosols or in industrial settings for VOC-heavy processes. Maintenance is straightforward, with generators lasting thousands of hours, but pairing with HEPA systems maximizes efficacy.

Key Differences Between Negative Air

Machines and Air Purifiers

When comparing negative air machines vs air purifiers, the distinctions lie in their primary functions, filtration methods, and ideal applications. Negative air machines focus on containment and high-volume particulate removal, creating isolated zones to prevent contaminant spread. Air purifiers, particularly those for odor, VOC, and bio, emphasize chemical neutralization and surface sanitization, addressing gaseous threats that HEPA filters alone can't handle.

Functionally, a negative air machine acts like a vacuum for entire rooms, using negative pressure to control airflow direction. An air purifier recirculates or enhances treated air, often as an add-on. In terms of airflow, negative machines boast higher CFM ratings for rapid air changes, while purifiers prioritize targeted destruction over volume.

Filtration-wise, negative air machines rely on mechanical HEPA and pre-filters, excelling at dust and spores but limited on gases. Air purifiers use oxidative processes, breaking down VOCs and odors without trapping them. This makes negative machines better for construction dust control and air purifiers superior for smell elimination in restoration.

To illustrate, in a hospital renovation, a negative air machine might isolate the work area, while an air purifier polishes the exhaust to eliminate any residual odors or microbes. Understanding these differences ensures you select the right tool—or combination—for optimal air quality.

Pros and Cons: Weighing the Options

Evaluating the pros and cons of negative air machines vs air purifiers reveals their strengths in complementary scenarios.

Starting with negative air machines:

Pros:

- Superior containment for hazardous materials like asbestos or lead.

- High CFM for quick air turnover in large spaces.

- Compliance with ICRA and OSHA for professional credibility.

- Versatile modes: negative pressure, positive pressure, or recirculation.

- Durable construction for demanding environments.

Cons:

- Bulkier and heavier, less ideal for small spaces.

- Higher energy consumption due to powerful fans.

- Limited efficacy against gaseous pollutants without add-ons.

- Requires ducting and setup for optimal use.

For air purifiers focused on odor, VOC, and bio:

Pros:

- Effective molecular breakdown of chemicals and smells.

- Safe for continuous use in occupied areas.

- Portable and quiet, enhancing user comfort.

- Complements other systems for comprehensive purification.

- Low maintenance with long-lasting generators.

Cons:

- Not designed for particulate containment or high-volume scrubbing.

- May require pairing with HEPA units for full-spectrum coverage.

- Less effective in extremely large or heavily contaminated zones.

- Initial investment in advanced tech can add up for multiples.

By balancing these factors, professionals can avoid common pitfalls, such as using a purifier alone in a dusty abatement project, which could lead to incomplete filtration.

When to Use Each: Real-World Applications

and Case Studies

Choosing between a negative air machine and an air purifier depends on your project's demands. For construction in occupied healthcare facilities, negative air machines are indispensable. Imagine a hospital wing renovation: Dust from demolition could endanger immunocompromised patients. A unit like the OA2200CMED, with its medical-grade 99.99% HEPA, creates a barrier, achieving 6-12 air changes per hour as per ICRA Class IV requirements.

In contrast, for odor control after a fire, an air purifier excels. Smoke residues linger, causing health issues and delaying reoccupation.

In industrial settings, negative machines handle silica dust from grinding, complying with silica standards, while purifiers manage welding fumes' chemical components. For home use, scaled-down versions address allergies, but professionals benefit from commercial-grade reliability.

How Negative Air Machines and Air

Purifiers Work Together

Rather than viewing negative air machines vs air purifiers as rivals, consider them allies in a layered filtration strategy. Integrating them creates a synergistic system: The negative machine handles initial containment and particulate removal, then ducts its exhaust to the purifier for gaseous polishing.

For example, in flood restoration, negative machines dry and filter mold-laden air, while purifiers eliminate musty odors and biohazards. This duo ensures compliance and enhances worker safety, reducing respiratory claims.

Technically, compatibility is key—models like OmniAire allow seamless connections via flex ducts. Benefits include broader contaminant coverage, energy efficiency (by avoiding redundant systems), and improved indoor air quality metrics, often measured by particle counters or VOC sensors.

Buying Guide: Factors to Consider

When shopping for a negative air machine or air purifier, prioritize CFM ratings, filter efficiency, and build quality. For negative machines, look for variable speeds and UL/CSA certification. Air purifiers should feature proven oxidation tech without ozone byproducts.

Maintenance and Best Practices

Regular upkeep extends lifespan: Change pre-filters weekly in heavy use, HEPA every few months. Clean housings to prevent buildup. For purifiers, monitor generator output. Follow manufacturer guidelines for peak efficiency.

Click Here to explore top-rated negative air machines and discover advanced air purifiers for odor, VOC, and bio control Here.

FAQ

What is the main difference between a negative air machine and an air purifier?

A negative air machine creates negative pressure to contain and filter particulates like dust and spores, while an air purifier neutralizes gaseous contaminants such as odors, VOCs, and biological agents through oxidation.

Can I use a negative air machine as an air purifier?

Negative air machines can add carbon filters for basic odor control, but they're not as effective as dedicated air purifiers for VOC and bio removal. Combining both is often best.

Are air purifiers safe for occupied spaces?

Yes, professional air purifiers like those for odor and VOC are designed for continuous use around people and pets, without producing harmful ozone.

What contaminants do air purifiers target that negative machines don't?

Air purifiers excel at breaking down VOCs (e.g., formaldehyde), odors (e.g., smoke), and biohazards (e.g., bacteria), which pass through HEPA filters.

Is maintenance different for each?

Negative air machines require frequent filter changes due to particulate buildup, while air purifiers need periodic generator checks but less overall upkeep.

Can these systems help with allergy relief?

Both can, but negative machines reduce airborne allergens via HEPA, and purifiers eliminate mold byproducts and VOCs that trigger symptoms.