Posted by Spycor LLC on Dec 18th 2025

Selecting the right surface protection for a large-scale construction site or a sensitive commercial renovation is often the difference between a profitable handover and a costly repair bill. In environments where heavy foot traffic, falling tools, and hot work are constant variables, standard drop cloths or cardboard covers are insufficient.

Cover Guard® has emerged as the industry standard for high-traffic commercial renovations. As a premium, flame-retardant floor protector, it offers a level of durability and safety compliance that disposable alternatives simply cannot match. Below, we examine why Cover Guard is the preferred choice for protecting high-value surfaces during the most demanding construction and restoration phases.

The Evolution of Surface Protection in

Commercial Construction

Traditional floor protection—such as rosin paper or corrugated plastic—often fails in "active" construction zones. These materials tear under the weight of scissor lifts, become slippery when wet, and pose significant fire risks.

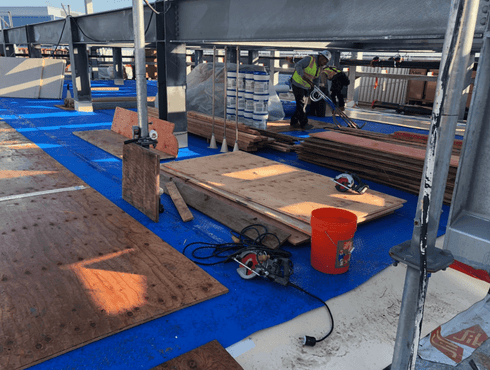

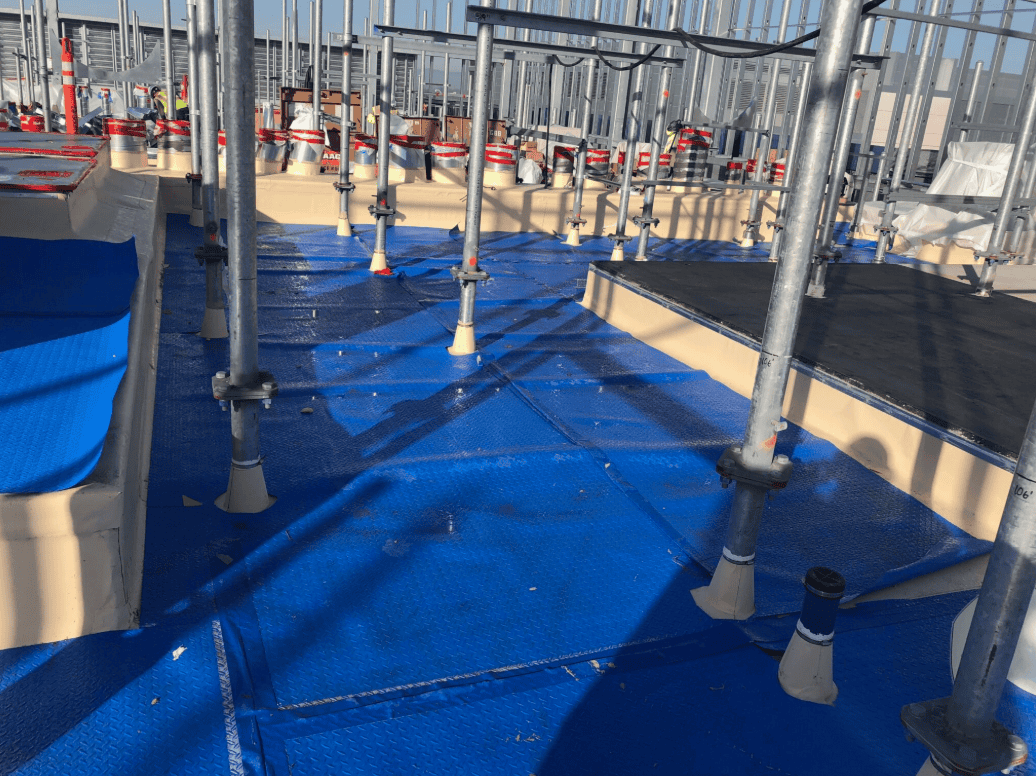

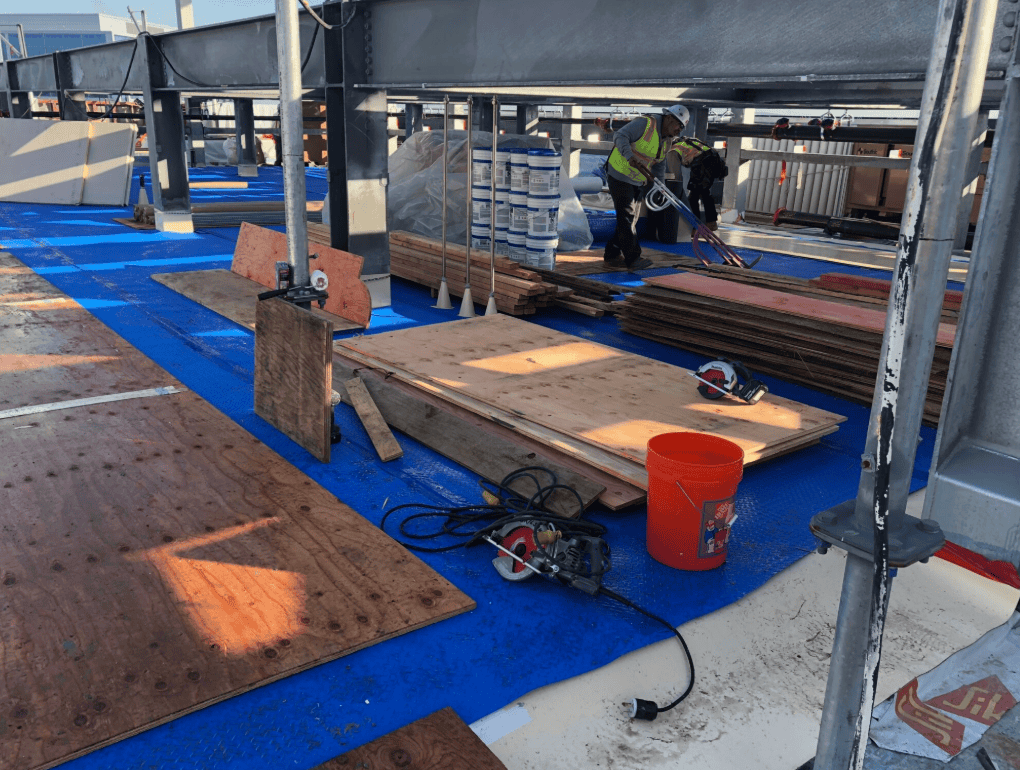

High-traffic commercial renovations require a modular, heavy-duty solution. This is where Cover Guard temporary surface protection material excels. Engineered from high-density molded polyethylene, it provides a physical barrier against impacts, chemicals, and moisture, while simultaneously addressing the stringent safety requirements of modern job sites.

Why Cover Guard® is the Superior Choice

for High-Traffic Zones

When evaluating materials for a project, contractors prioritize three factors: durability, safety, and cost-efficiency. Cover Guard is designed to hit all four.

1. Flame Retardant and NFPA 701 Compliant

In commercial buildings, hospitals, and marine environments, fire safety is non-negotiable. Cover Guard (specifically the blue FR version) is a flame-retardant floor protector that complies with NFPA 701 standards. This allows it to be used not only as floor protection but also for vertical applications, such as draping walls, bulkheads, and equipment, without increasing the fire load of the workspace.

2. High-Impact Puncture Resistance

Commercial renovations often involve heavy equipment like scaffolding, carts, and light machinery. Available in thicknesses ranging from 10 mil to 40 mil, Cover Guard provides a puncture-resistant shield that prevents scratches, dents, and gouges on delicate surfaces like hardwood, polished concrete, and marble.

3. Enhanced Slip Resistance (Diamond Plate Finish)

Safety officers prioritize products that reduce the risk of "slip and fall" accidents. Cover Guard’s signature diamond plate pattern provides an anti-slip surface that meets ASTM C 1028-07 standards. This embossed texture ensures that even in wet or dusty conditions, workers maintain traction.

4. Waterproof and Chemical Resistant

Unlike cardboard-based protectors that disintegrate when exposed to spills, Cover Guard is entirely waterproof and resistant to most industrial chemicals and solvents. This makes it ideal for painting, drywalling, and masonry work where moisture and wet debris are common.

Strategic Applications: Where to Use

Cover Guard®

Because it is both flexible and incredibly tough, Cover Guard is used across several specialized industries:

-

Commercial Refurbishment: Protecting VCT, tile, and hardwood in office buildings and retail spaces during layout changes. Its high-impact resistance ensures that heavy rolling loads and foot traffic do not mar finished surfaces during aggressive remodeling phases.

-

Hospitals and Laboratories: Its anti-static properties and clean-removal design (it uses no adhesives) make it safe for sensitive medical environments. By eliminating the risk of adhesive residue or dust accumulation, it helps maintain the strict hygiene standards required in sterile settings.

-

Marine and Aviation: Used extensively in shipyards and aircraft hangars for deck and interior protection during outfitting. The material's flame-retardant properties provide a critical layer of safety in environments where welding or heavy machinery maintenance is a daily occurrence.

-

New Construction: Shielding green concrete or finished flooring from HVAC staging and electrical work. The breathable nature of the material allows concrete to cure properly while providing a robust barrier against dropped tools and construction debris.

Maximizing ROI: A Reusable and Recyclable Solution

One of the most significant advantages of Cover Guard is its longevity. While traditional materials are "one and done," Cover Guard is reusable. Its durable polyethylene construction allows it to be cleaned, rolled up, and transported to the next job site. This not only reduces the cost-per-project but also supports sustainable building practices by minimizing landfill waste. When the material finally reaches the end of its life cycle, it is 100% recyclable.

Expert Tips for Installing Cover Guard®

To ensure maximum visibility and protection on your site, follow these best practices:

-

Choose the Right Mil: Use 10 mil for vertical surfaces or light dust protection. For heavy traffic and equipment, the 25 mil or 40 mil options are recommended.

-

Clean the Subfloor: Ensure the floor is free of grit and debris before unrolling the protector to prevent "grinding" particles into the finish.

-

Secure the Seams: Use Cover Guard Seam Tape to join rolls. This prevents dust and liquids from seeping through the gaps while maintaining the flame-retardant integrity of the entire covering.

-

Avoid Adhesives on the Floor: Since Cover Guard is heavy and textured, it often stays in place without being taped directly to the floor, protecting delicate finishes from adhesive residue.

Don’t risk your project’s success on inferior materials. Protect your investment with the industry’s most trusted flame-retardant surface protection.

Order Now at spycor.com for competitive pricing, technical expertise, and fast shipping on all Cover Guard® products.

Frequently Asked Questions (FAQ)

What is Cover Guard® made of?

Cover Guard is manufactured from high-strength molded polyethylene. The blue version is specially formulated with flame-retardant additives to meet international safety standards.

Does Cover Guard meet fire safety regulations?

Yes. The blue Cover Guard is flame retardant and complies with the NFPA 701 standard. It is also NAVSEA certified for use in marine and military applications.

Can Cover Guard be used on hardwood floors?

Absolutely. It is an excellent choice for hardwood as it provides impact protection without the use of adhesives that can leave a sticky residue or damage the wood's finish.

How do I choose between the smooth and diamond plate finishes?

The diamond plate finish is recommended for high-traffic areas where slip resistance is a priority. The smooth finish is often used for draping equipment or protecting vertical surfaces where a textured grip is not required.

Is Cover Guard waterproof?

Yes, it is 100% waterproof and resistant to water, most oils, chemicals, and solvents, making it perfect for both interior and exterior renovation projects.

How many times can I reuse Cover Guard?

Depending on the intensity of the traffic and the mil thickness chosen, Cover Guard can often be used for 5 to 10 project cycles if properly cleaned and stored between uses.

Where can I buy Cover Guard for commercial projects?

You can buy the full range of Cover Guard thicknesses and roll sizes at Spycor.com, your authorized distributor for professional-grade surface protection.